Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

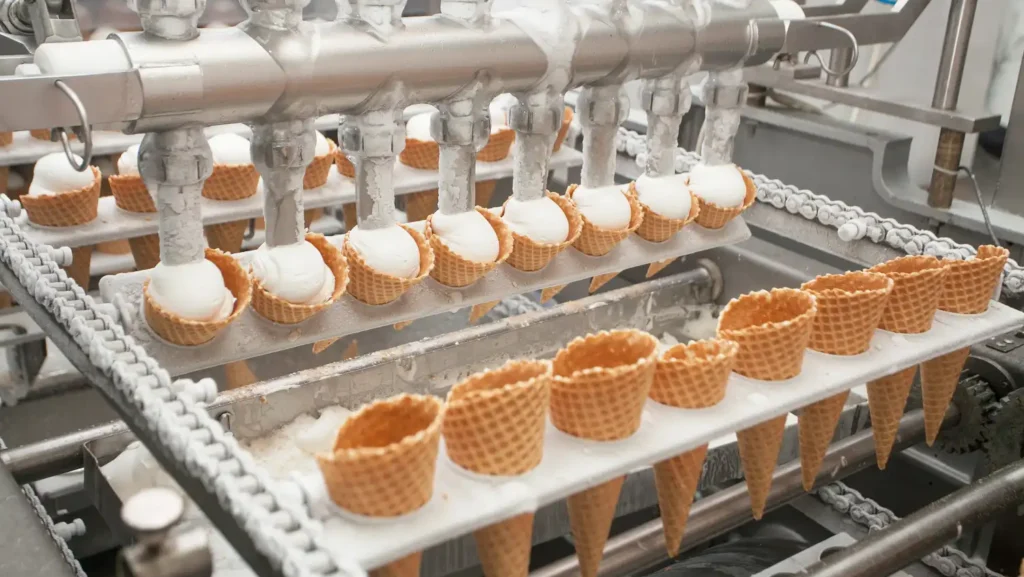

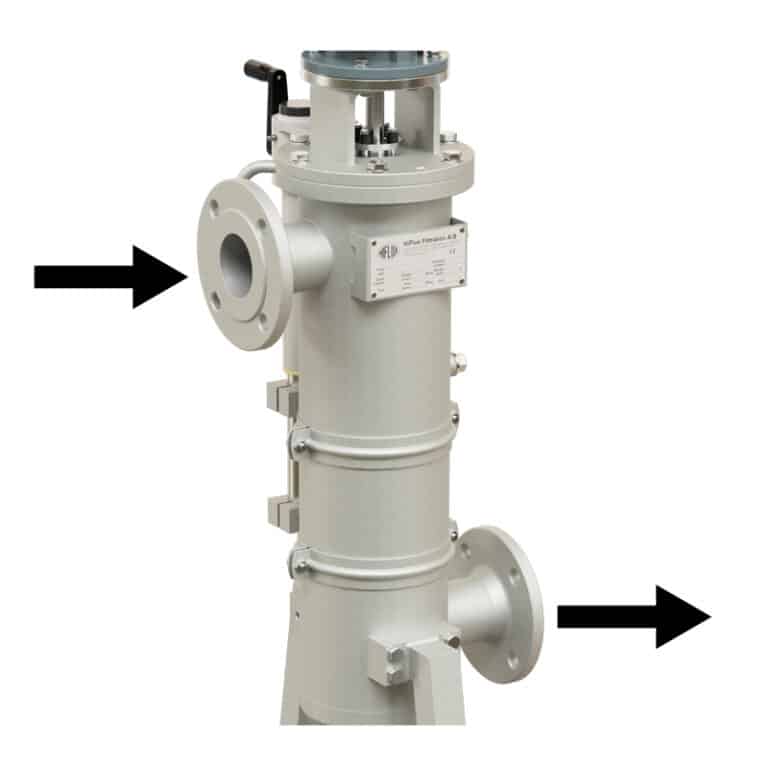

In the competitive world of ice cream production, achieving a balance between quality and efficiency is crucial. HiFlux Automatic Liquid Filtration Systems are pivotal in removing unwanted particles from ice cream mixes, ensuring a smooth, high-quality product while optimizing the production process. These systems maintain continuous operation, significantly reducing downtime and enhancing productivity. Their advanced self-cleaning technology streamlines the workflow, enabling ice cream manufacturers to focus on crafting delicious products without the interruption of filtration processes.

Customized Filtration Solutions: A Perfect Fit

Recognizing the unique needs of the ice cream industry, HiFlux Filtration A/S offers customized filtration solutions designed to integrate seamlessly into existing production lines. Whether addressing the challenges of varying mix viscosities or ensuring the retention of valuable flavor particles while excluding contaminants, HiFlux’s tailored systems are a perfect fit. This approach not only solves specific filtration challenges but also avoids the additional costs associated with generic solutions, making it an ideal choice for ice cream producers.

Advanced Filtration Technology: Ensuring Superior Qualit

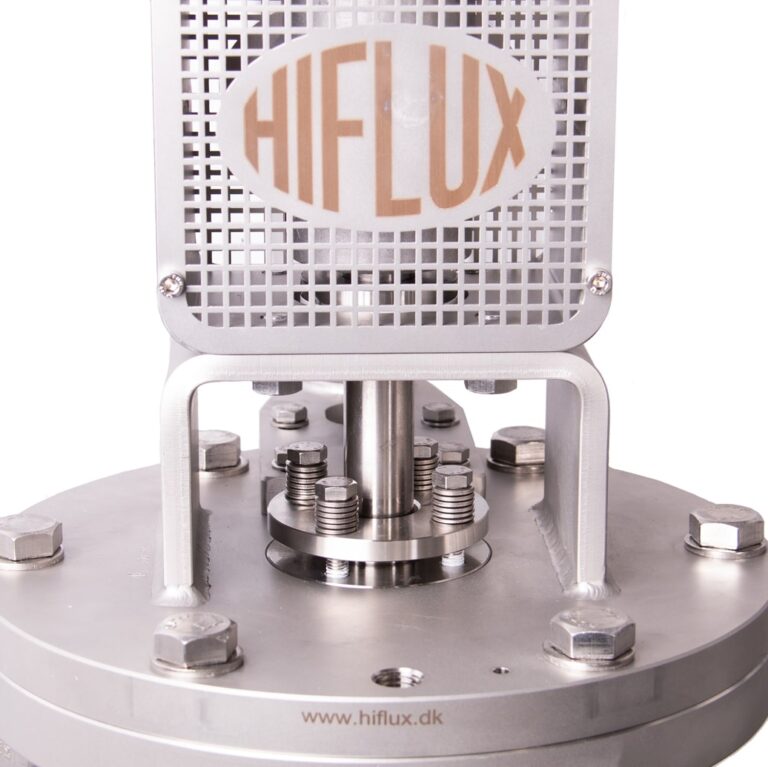

HiFlux Filtration Systems leverage cutting-edge technology to guarantee the superior quality of ice cream products. By efficiently removing impurities and preventing the entry of foreign materials, these systems ensure a consistent and premium quality mix. Continuous cleaning of the filter element maintains a steady filtration capacity, eliminating the risk of quality variations and securing the integrity of the final product. This advanced technology upholds the rigorous quality standards demanded in the ice cream industry.

Cost-Effective and Durable: A Smart Investment

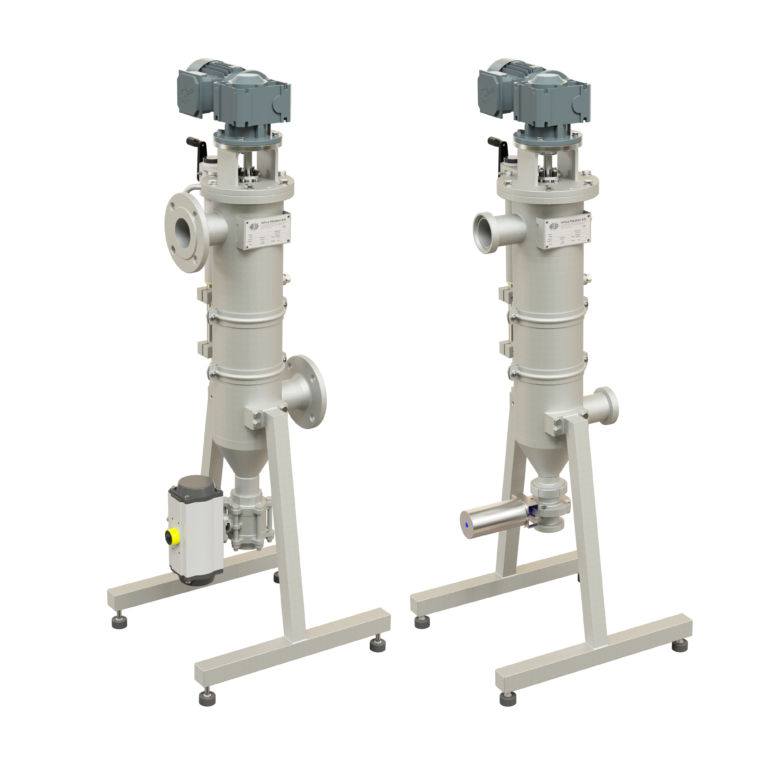

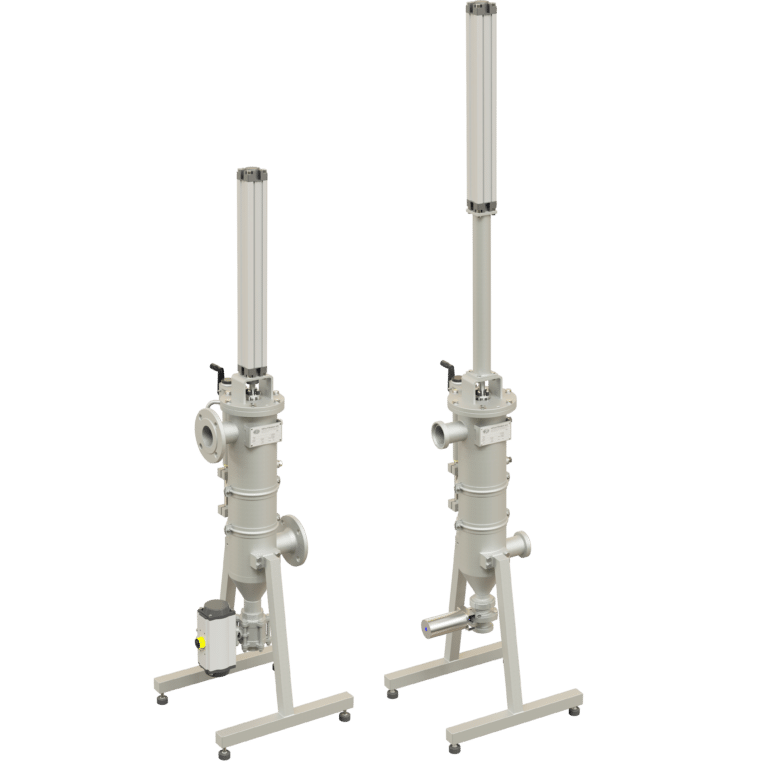

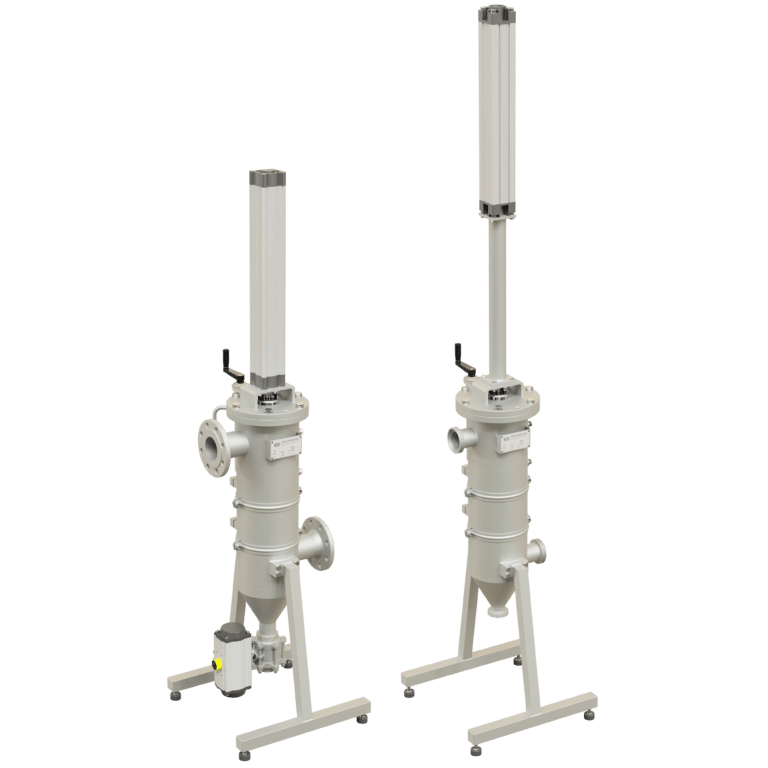

Opting for HiFlux Filtration Systems is a prudent investment for ice cream manufacturers seeking durable and cost-effective filtration solutions. The longevity of the filter inserts and the robust design minimize maintenance expenses, while the system’s automated cleaning and uninterrupted flow processes significantly reduce operational costs. The economic and operational advantages provided by HiFlux Systems make them a strategic investment for businesses aiming for sustainability and profitability.

Flexibility and Future-Proofing: Adapting to Evolving Needs

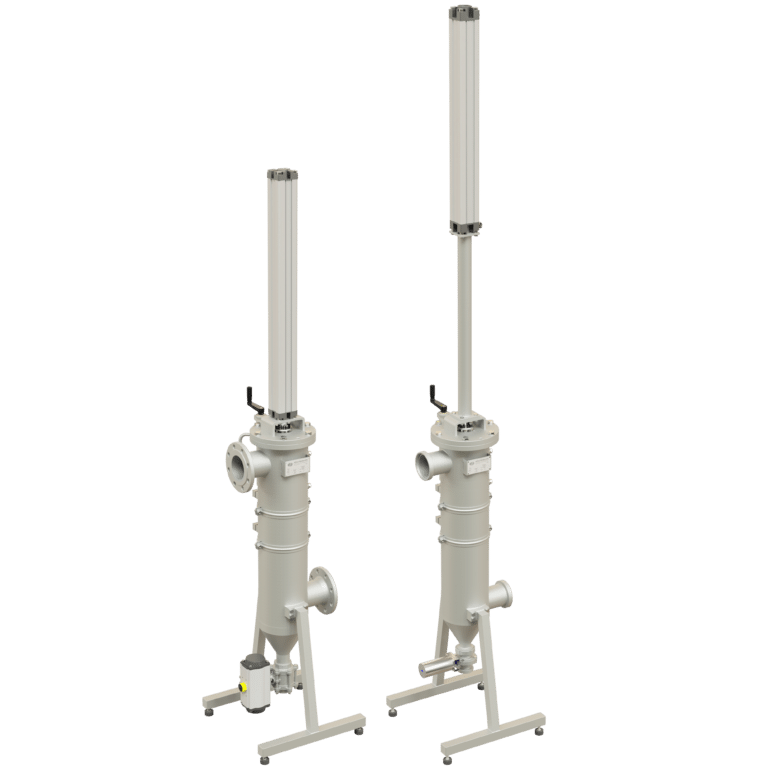

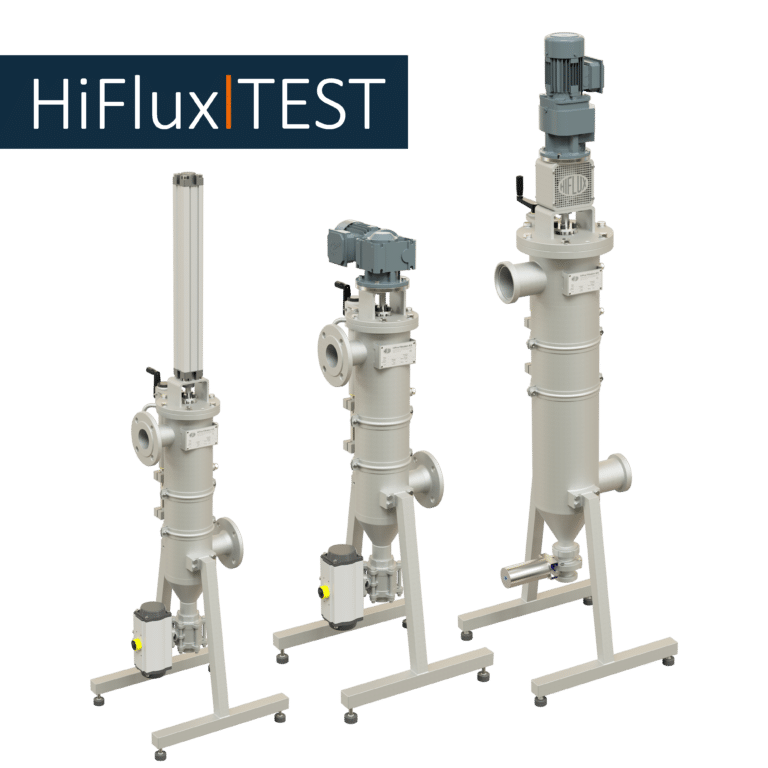

HiFlux Filtration Systems are designed with flexibility and future-proofing in mind, accommodating the dynamic requirements of the ice cream industry. Thanks to their modular design, these systems can be easily adapted for new product lines or changes in production needs, ensuring that they remain an effective solution for years to come. This flexibility makes HiFlux Systems a future-proof investment, providing ice cream producers with a reliable filtration solution that can evolve with their business.

Conclusion: Enhancing Production with HiFlux

For ice cream manufacturers, HiFlux Automatic Liquid Filtration Systems represent the gold standard in filtration technology, offering an all-encompassing solution that enhances product quality and production efficiency. The hygienic design of the HiFlux auto-line filters, specifically tailored for the food industry, ensures that ice cream products are not only delicious but also meet the highest standards of food safety and quality. By partnering with HiFlux, ice cream producers can achieve exceptional results, optimizing their operations and setting new benchmarks in the industry.