Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

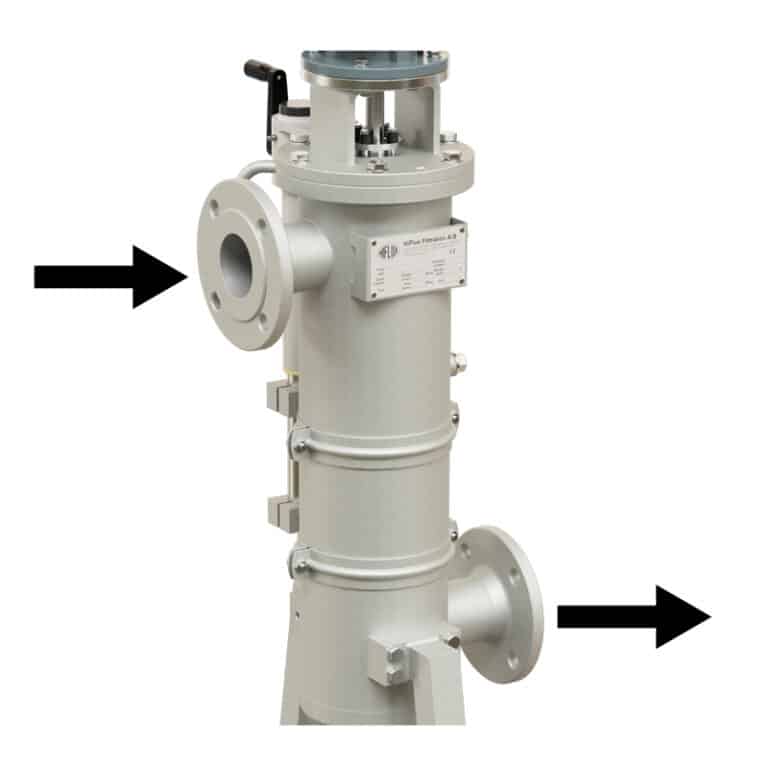

In the production of monomers and polymers, the removal of particulate contamination is crucial for achieving product purity and operational efficiency. HiFlux Automatic Liquid Filtration Systems stand out as the solution of choice for this sector, providing a seamless method to filter out impurities from these critical materials. These systems maintain a continuous flow, ensuring uninterrupted production and the elimination of process inefficiencies. The self-cleaning feature of HiFlux filters minimizes downtime and labor associated with manual cleaning, directly contributing to a more streamlined and cost-effective manufacturing process.

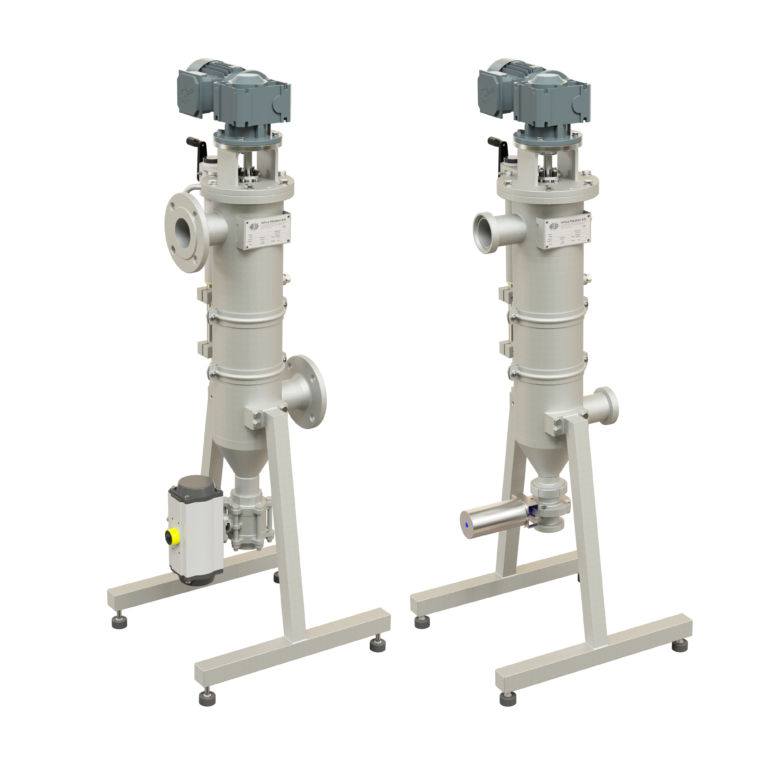

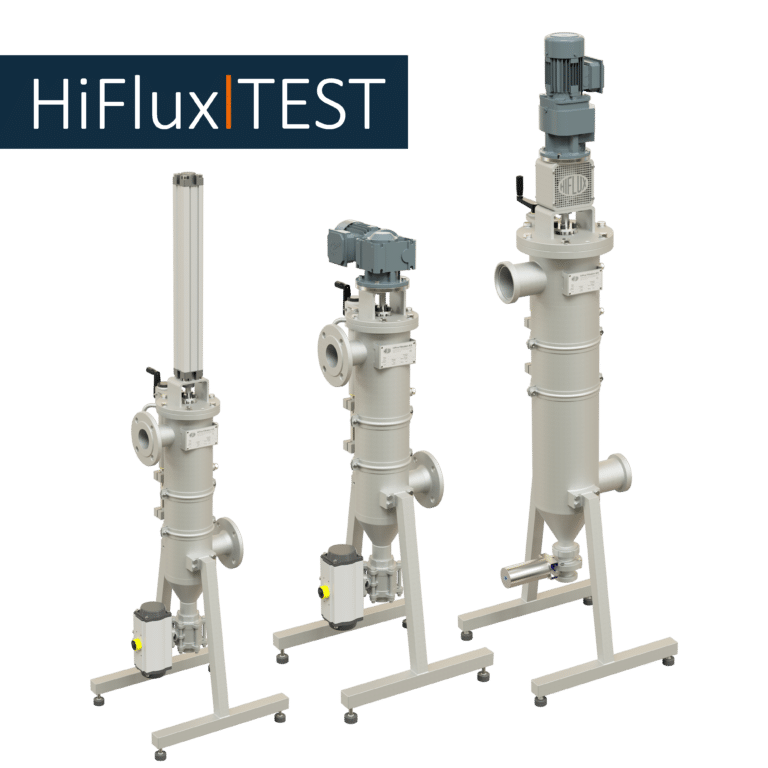

Customized Filtration Solutions: A Perfect Fit

Recognizing the diverse nature of monomer and polymer production, HiFlux Filtration A/S excels in offering customized filtration solutions tailored to the unique challenges of these substances. Whether the task involves handling high-viscosity polymers or ensuring the efficient separation of monomer particles, HiFlux’s bespoke systems integrate seamlessly into existing processing lines. This personalized approach not only meets the specific filtration needs but also optimizes the overall investment by reducing the need for extensive modifications to production setups.

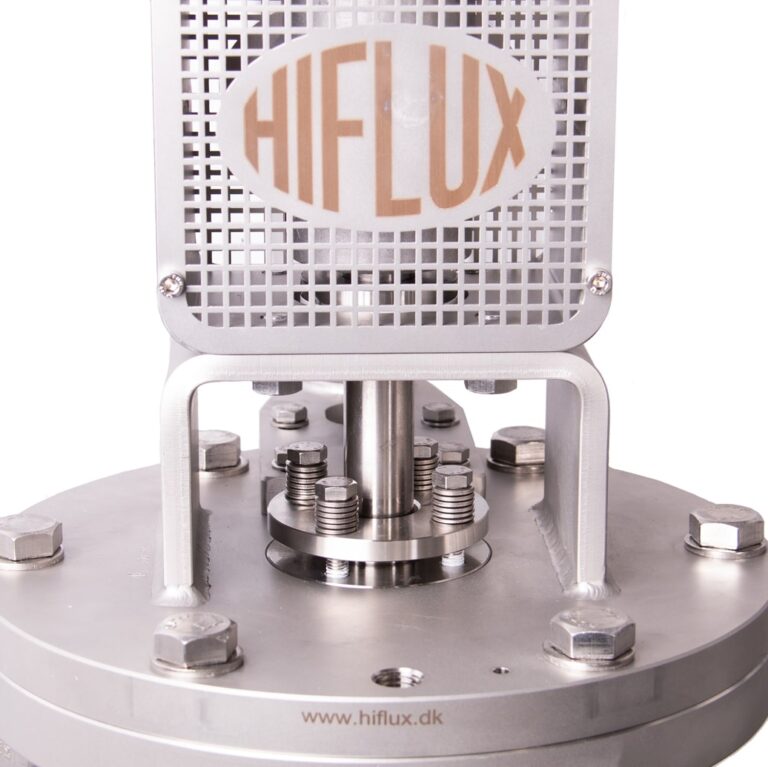

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems incorporate advanced technology to safeguard the superior quality of monomers and polymers. The precision in removing unwanted particles and preventing contamination is paramount in this field, where the quality of the end product is directly influenced by its purity. Continuous scraping and cleaning mechanisms within the HiFlux filters maintain a consistent filtration efficiency, ensuring that the final products are of the highest quality, free from impurities that could compromise their performance or safety.

Cost-Effective and Durable: A Smart Investment

Opting for HiFlux Filtration Systems is a financially savvy choice for producers in the monomer and polymer sector. The durability of the systems, combined with their long filter insert lifespan, significantly lowers maintenance overheads. Moreover, the operational cost benefits, derived from the automatic, continuous flow process and reduced product loss, underscore the cost-effectiveness of these systems. HiFlux’s solutions are not just about immediate gains but also about securing long-term operational savings and efficiency.

Flexibility and Future-Proofing: Adapting to Evolving Needs

The modular design of HiFlux Filtration Systems exemplifies their adaptability and future-proof nature, crucial for the dynamic monomer and polymer industry. As production demands evolve or as new formulations are developed, these systems can be easily modified to accommodate new filtration requirements. This flexibility ensures that HiFlux systems continue to provide value long into the future, adapting to changes in production processes or product specifications without necessitating complete system overhauls.

Conclusion: Enhancing Production with HiFlux

For the monomer and polymer industry, HiFlux Automatic Liquid Filtration Systems offer an unmatched blend of quality assurance, operational efficiency, and adaptability. The implementation of HiFlux technology not only meets the immediate filtration needs of these sectors but also positions manufacturers for future growth and innovation. By partnering with HiFlux Filtration A/S, producers can look forward to achieving and maintaining the highest standards in product quality and production performance, ensuring their competitive edge in the market.