Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

The production of melted cheese involves precise control over texture and consistency, where the removal of unwanted particulates is crucial to achieving the desired product quality. HiFlux Automatic Liquid Filtration Systems, featuring advanced hygienic filters, are specifically designed to enhance the quality and efficiency of melted cheese production. These systems utilize self-cleaning technology to minimize downtime and manual labor, ensuring that the melted cheese is processed under the highest standards of hygiene. This is vital for maintaining the continuous, high-volume production required in the food industry, ensuring that melted cheese meets both regulatory standards and consumer expectations.

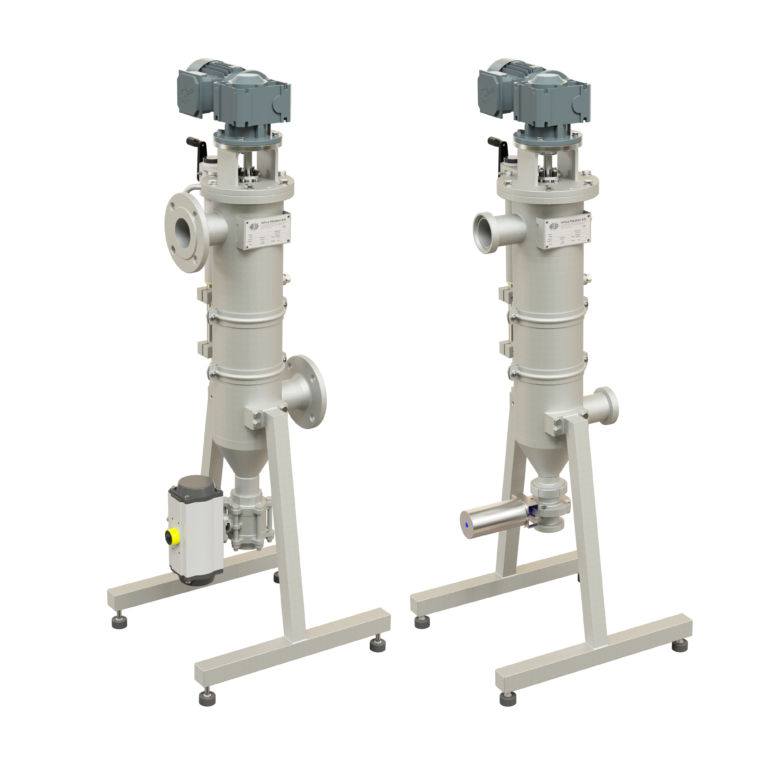

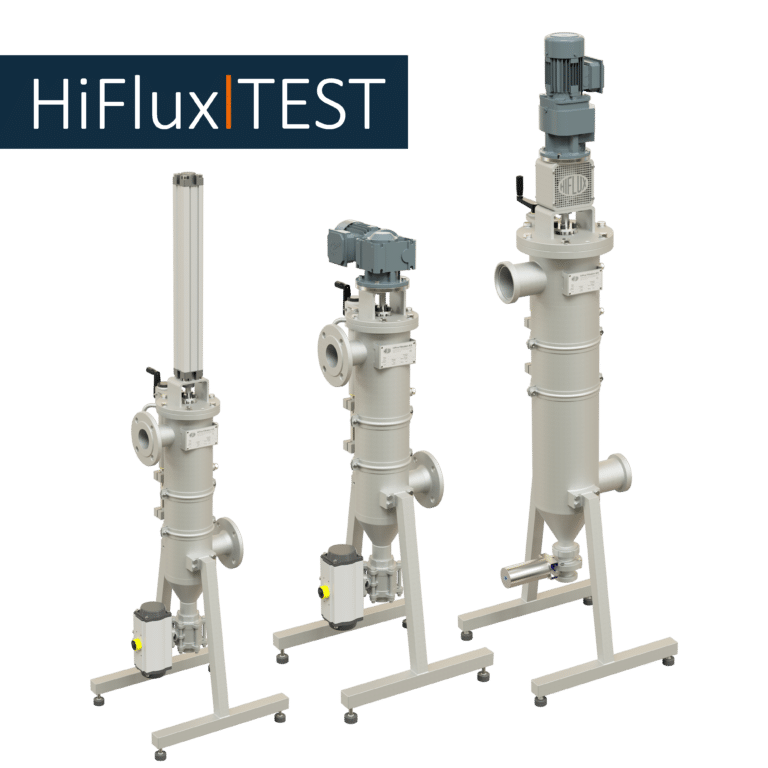

Customized Filtration Solutions: A Perfect Fit

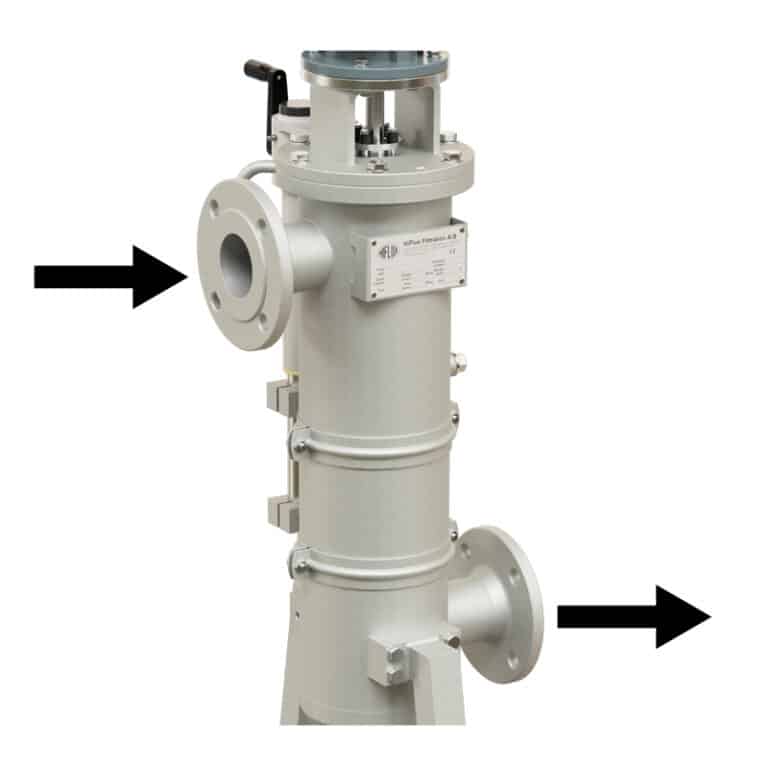

Recognizing the specific challenges associated with filtering melted cheese, including its high viscosity and sensitivity to temperature changes, HiFlux Filtration A/S offers customized filtration solutions tailored to meet these unique needs. These systems are engineered to seamlessly integrate into existing melted cheese production lines, providing an optimal fit that ensures efficient, continuous filtration. By addressing the particular requirements of melted cheese filtration, HiFlux helps manufacturers maintain the quality and consistency of their product, with minimal impact on production workflows.

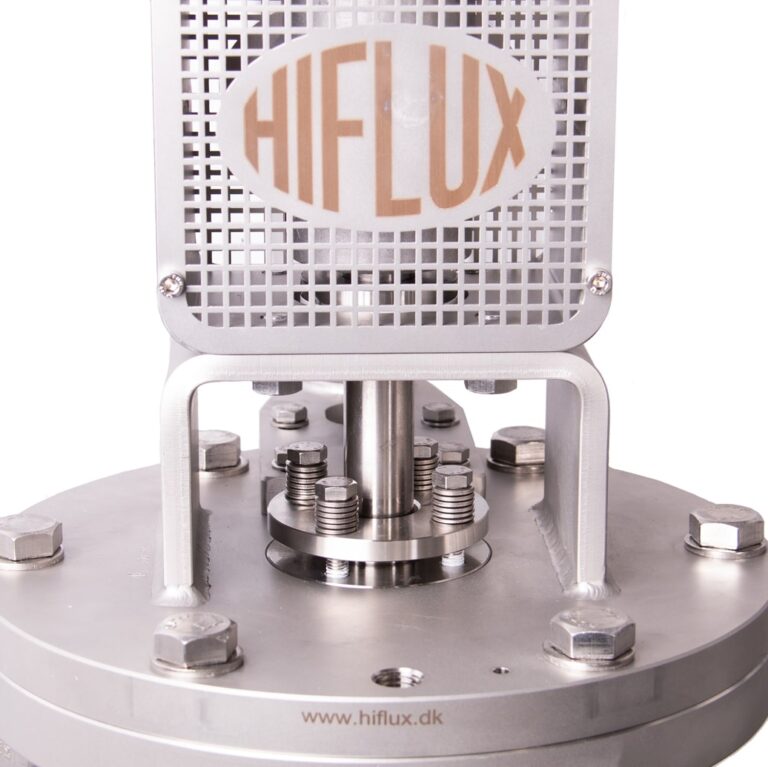

Advanced Filtration Technology: Ensuring Superior Quality

Utilizing state-of-the-art filtration technology, HiFlux systems excel in removing all types of particulates from melted cheese, thus safeguarding its quality and enhancing the final product. The hygienic design of these filtration systems adheres to the strictest standards of food safety, crucial for preventing contamination and spoilage. This level of filtration precision is essential for producing high-quality melted cheese, as it directly influences the product’s flavor, texture, and shelf life, helping manufacturers meet consumer expectations and regulatory requirements.

Cost-Effective and Durable: A Smart Investment

The durability and low maintenance features of HiFlux Filtration Systems make them an ideal choice for melted cheese production. Designed to withstand the demanding conditions of food processing, these systems offer long service life and reduced operational costs, thanks to their self-cleaning functionality and robust construction. This results in a lower total cost of ownership and a faster return on investment, aligning with the industry’s need for effective solutions that do not compromise on quality or safety.

Flexibility and Future-Proofing: Adapting to Evolving Needs

As consumer preferences and food safety standards continue to evolve, the need for adaptable and scalable filtration solutions becomes increasingly important. HiFlux Filtration Systems are designed with this flexibility in mind, allowing melted cheese producers to easily adjust their processes to meet changing requirements. This modular design ensures that manufacturers can future-proof their operations, maintaining efficiency and compliance without the need for significant reinvestment.

Conclusion: Enhancing Production with HiFlux

In summary, HiFlux Automatic Liquid Filtration Systems offer a comprehensive solution to the challenges of maintaining purity and quality in melted cheese production. By combining customizable, advanced filtration technology with a focus on cost-efficiency, hygiene, and sustainability, HiFlux Filtration A/S enables melted cheese manufacturers to optimize their production processes. This approach ensures the production of high-quality melted cheese products, meeting the demands of a dynamic food industry and contributing to the success and growth of cheese manufacturers worldwide.