Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

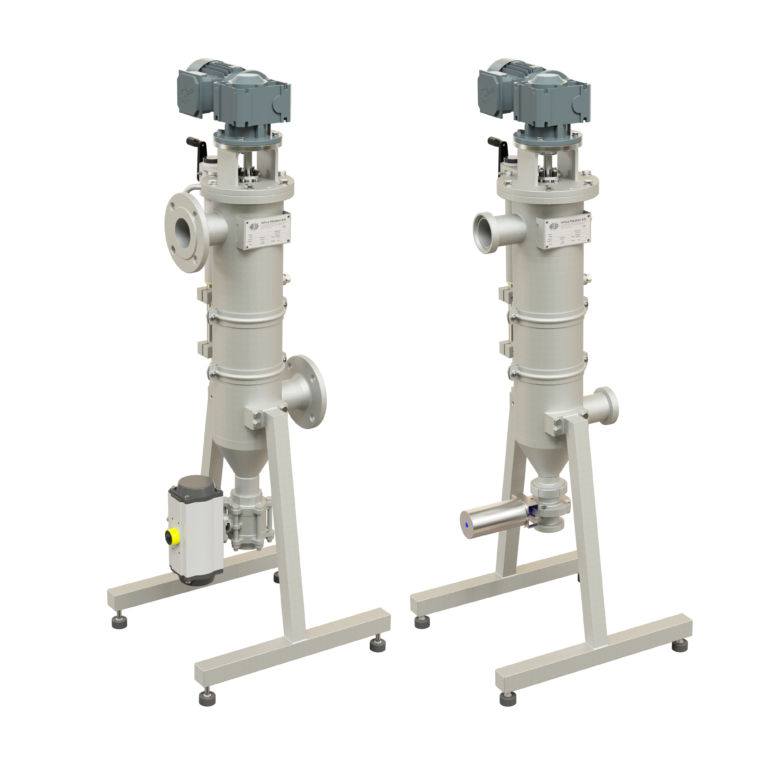

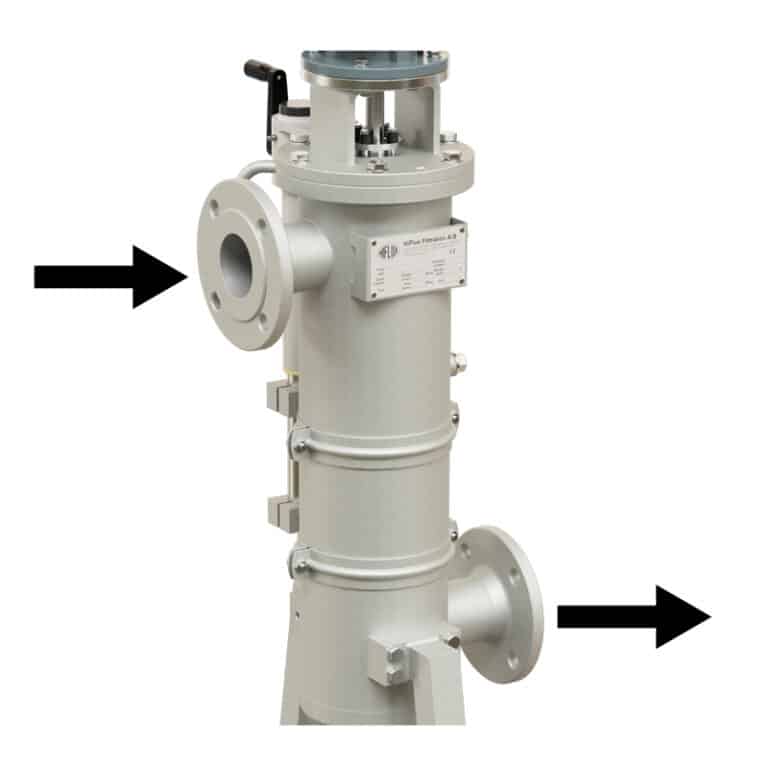

In the production of cream cheese, the consistency, texture, and purity of the product are essential for consumer satisfaction. HiFlux Automatic Liquid Filtration Systems, designed with hygienic filters, play a pivotal role in removing particulates from cream cheese, ensuring a smooth, high-quality final product. These systems significantly enhance both the quality and efficiency of cream cheese production by employing self-cleaning technology, which drastically reduces downtime and labor, a crucial advantage in maintaining the continuous, high-volume production required in the food industry.

Customized Filtration Solutions: A Perfect Fit

HiFlux Filtration A/S offers tailored hygienic filtration solutions that meet the unique requirements of cream cheese production. These customized systems are engineered to handle the specific viscosity and particulate profile of cream cheese, ensuring optimal filtration performance without compromising the product’s integrity. By providing solutions that can be seamlessly integrated into existing cream cheese processing lines, HiFlux guarantees an efficient, hygienic process that minimizes the need for extensive modifications, thereby reducing initial investment costs.

Advanced Filtration Technology: Ensuring Superior Quality

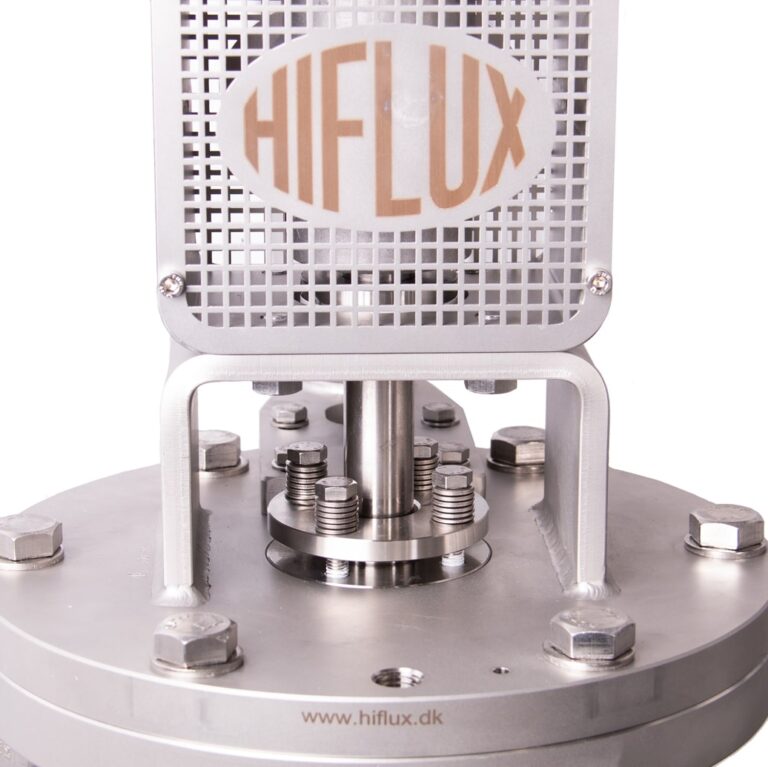

Utilizing advanced filtration technology, HiFlux systems are adept at removing all types of particulates from cream cheese, thereby safeguarding its quality, texture, and taste. The hygienic design of these filtration systems ensures compliance with the strictest food safety standards, crucial for maintaining consumer confidence and meeting regulatory requirements. This focus on advanced, hygienic filtration helps cream cheese manufacturers achieve a consistently high-quality product, essential for standing out in a competitive market.

Cost-Effective and Durable: A Smart Investment

The durability and low maintenance requirements of HiFlux Filtration Systems make them an ideal choice for cream cheese production. These systems are designed to withstand the demanding conditions of food processing, offering longevity and reduced operational costs through their self-cleaning functionality and robust construction. As a result, cream cheese manufacturers can enjoy significant savings over time, with a lower total cost of ownership and a quicker return on investment.

Flexibility and Future-Proofing: Adapting to Evolving Needs

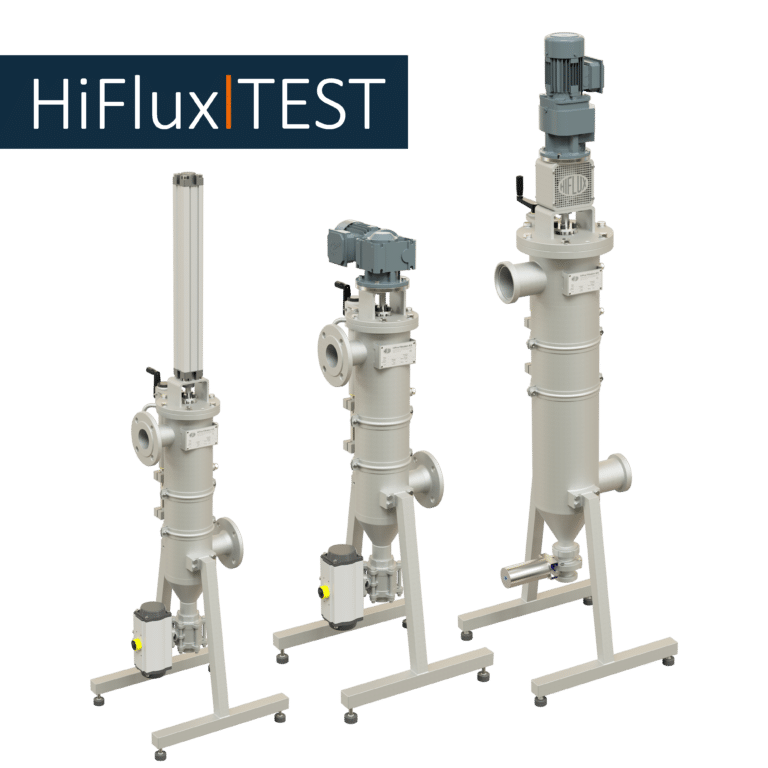

As consumer preferences and food safety standards continue to evolve, the need for adaptable and scalable filtration solutions becomes increasingly important. HiFlux Filtration Systems are designed with this flexibility in mind, allowing cream cheese producers to easily adjust their processes to meet changing requirements. This modular approach ensures that manufacturers can future-proof their operations, maintaining efficiency and compliance without the need for significant reinvestment.

Conclusion: Enhancing Production with HiFlux

In summary, HiFlux Automatic Liquid Filtration Systems provide a comprehensive solution to the challenges faced in cream cheese production, from maintaining product purity and quality to ensuring efficient, hygienic operations. By combining customizable, advanced filtration technology with a focus on cost-effectiveness and sustainability, HiFlux Filtration A/S enables cream cheese manufacturers to optimize their processes, achieve superior product quality, and remain competitive in the ever-changing food industry landscape.