Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

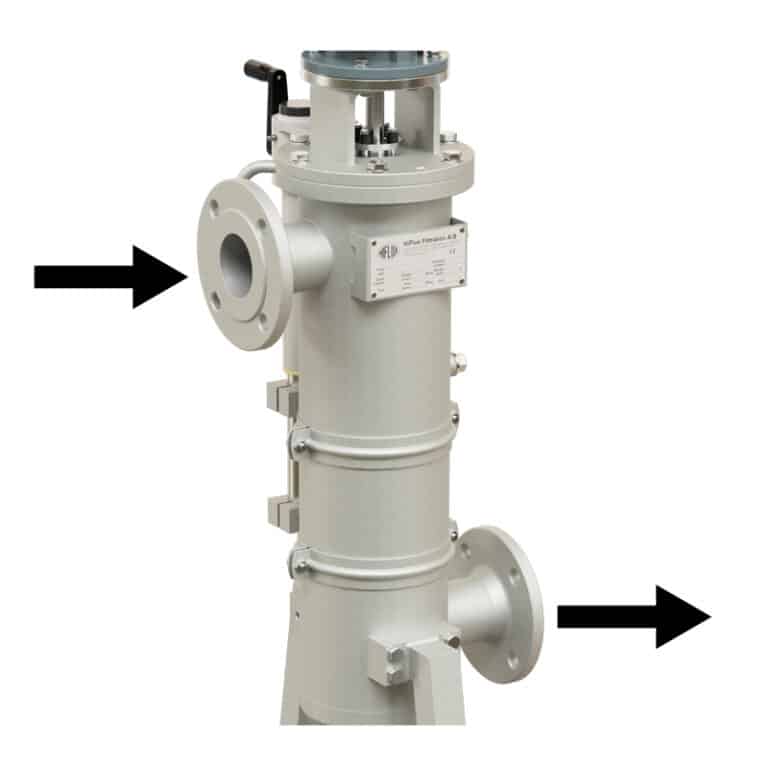

In the critical production of battery anode and cathode fluids, ensuring the safety and purity of these liquids is paramount, given their hazardous nature to both humans and the environment. HiFlux Automatic Liquid Filtration Systems are instrumental in removing dangerous particles from these fluids, significantly enhancing product safety and manufacturing efficiency. The self-cleaning technology embedded in these systems guarantees continuous operation, minimizing exposure risks to operators and reducing downtime. This efficiency boost, afforded by HiFlux’s innovative filtration solutions, directly translates to enhanced productivity and safety in battery fluid production.

Customized Filtration Solutions: A Perfect Fit

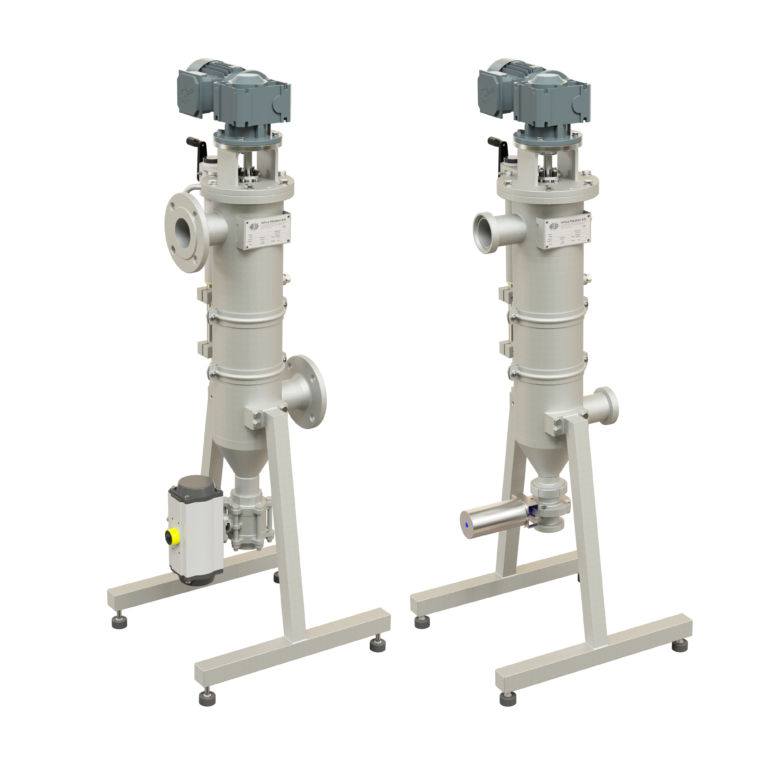

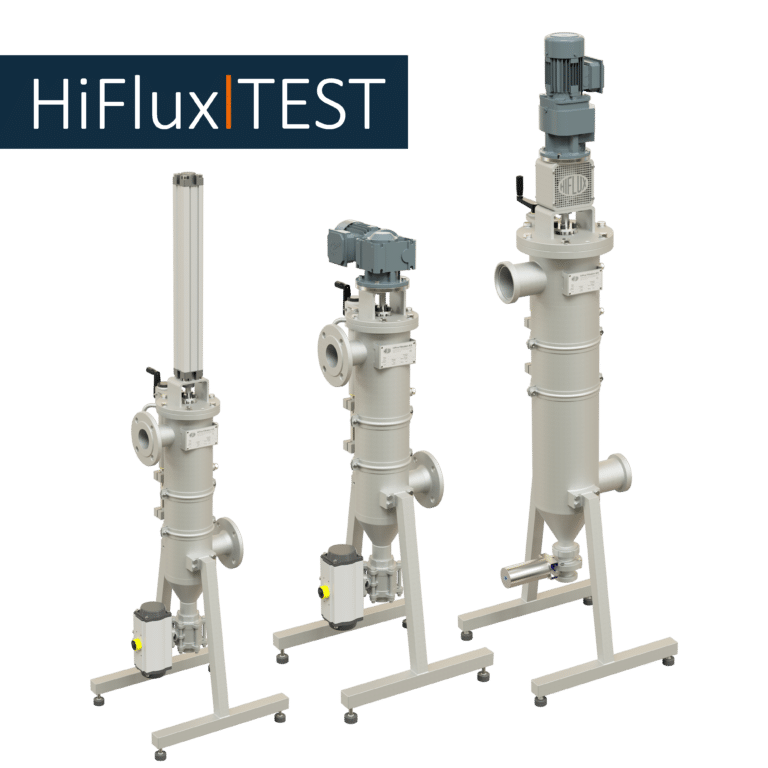

Recognizing the unique challenges posed by the filtration of battery anode and cathode fluids, HiFlux Filtration A/S offers tailor-made solutions that precisely meet these specific demands. Whether it’s handling highly corrosive fluids, managing high viscosity levels, or ensuring the removal of ultra-fine particulates without compromising the integrity of valuable components, HiFlux’s systems are designed to integrate flawlessly into existing manufacturing setups. This customized approach not only mitigates the inherent risks associated with battery fluid processing but also streamlines operations, making it a seamlessly adaptable solution for the industry.

Advanced Filtration Technology: Ensuring Superior Quality

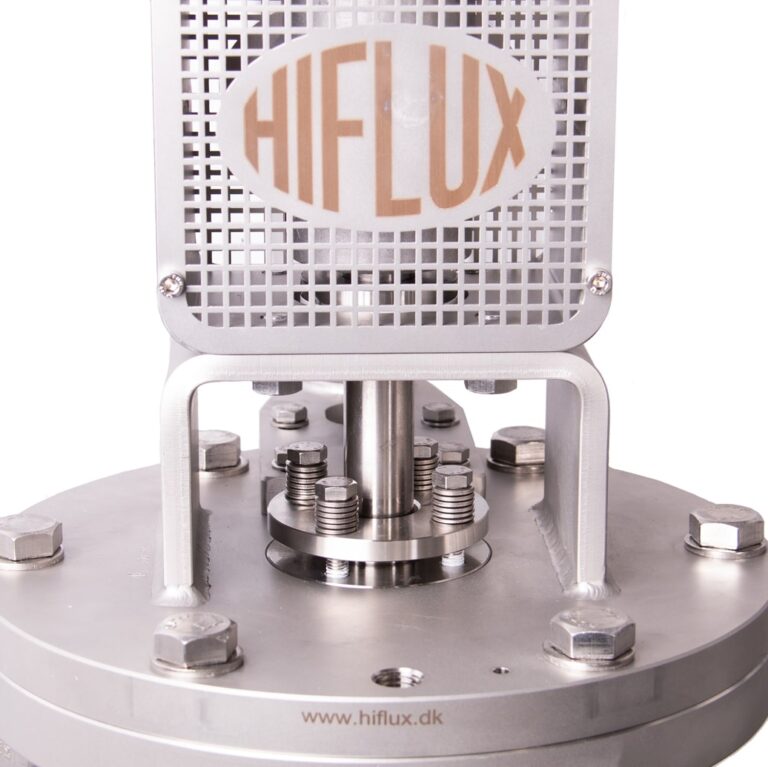

The advanced filtration technology of HiFlux Systems plays a crucial role in maintaining the highest standards of quality and safety in battery fluid production. By efficiently removing harmful particulates and preventing contamination, these systems ensure that the fluids used in battery anodes and cathodes are of superior quality. Continuous cleaning and maintenance of the filtration capacity prevent production interruptions, thereby maintaining a consistent and reliable manufacturing process. This level of quality control is essential for producing safe, high-performance batteries.

Cost-Effective and Durable: A Smart Investment

Investing in HiFlux Filtration Systems for the processing of battery fluids represents a cost-effective and durable choice for manufacturers. The robust design and long lifespan of the filter elements contribute to lower maintenance costs, while the automated, continuous flow process reduces labor expenses and enhances operational efficiency. The durability and effectiveness of HiFlux Systems make them an economical investment, offering long-term financial benefits and ensuring a safer production environment.

Flexibility and Future-Proofing: Adapting to Evolving Needs

HiFlux Filtration Systems are designed with flexibility and adaptability in mind, catering to the evolving needs of battery fluid production. The modular design allows for easy adjustments and upgrades, ensuring that the filtration system can adapt to new regulations, materials, and production technologies. This future-proof approach guarantees that manufacturers can rely on HiFlux Systems to meet both current and future filtration requirements, securing their investment and positioning them at the forefront of battery technology development.

Conclusion: Enhancing Production with HiFlux

In the domain of battery anode and cathode fluid production, HiFlux Automatic Liquid Filtration Systems offer unparalleled benefits in terms of safety, efficiency, and quality control. By leveraging HiFlux’s cutting-edge technology and customized solutions, manufacturers can achieve a significant competitive advantage, ensuring the production of safer, higher-quality battery components. With HiFlux, the industry is well-equipped to face the challenges of today and tomorrow, driving forward with innovation and sustainability at the core of operations.