Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

In the highly specialized field of baby food production, ensuring the purity and safety of liquid ingredients is paramount. HiFlux Automatic Liquid Filtration Systems, equipped with advanced hygienic filters, are specifically designed to meet these stringent requirements. By removing particulates from liquids used in baby food, these systems ensure the highest product quality and safety, crucial for protecting infants’ health. Utilizing self-cleaning technology, HiFlux systems significantly reduce downtime and labor, enhancing production efficiency while upholding the strictest standards of hygiene.

Customized Filtration Solutions: A Perfect Fit

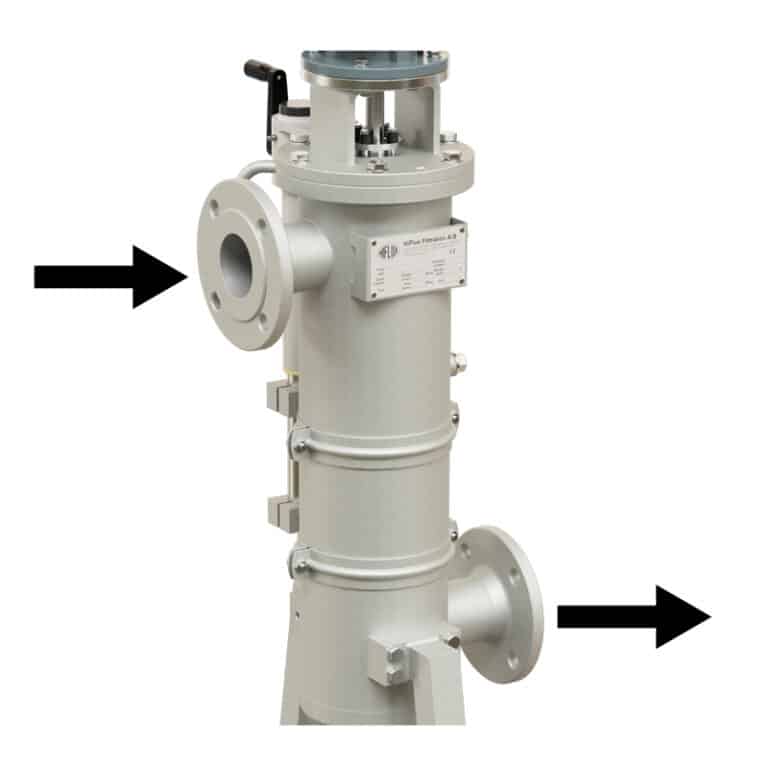

Understanding the unique sensitivities and regulatory standards associated with baby food production, HiFlux Filtration A/S offers customized filtration solutions. These systems are engineered to integrate seamlessly into baby food processing lines, providing an optimal fit that addresses the specific requirements of liquid filtration in this context. By facilitating the efficient and continuous filtration of liquids, HiFlux helps manufacturers maintain product integrity and safety, crucial for consumer trust and regulatory compliance.

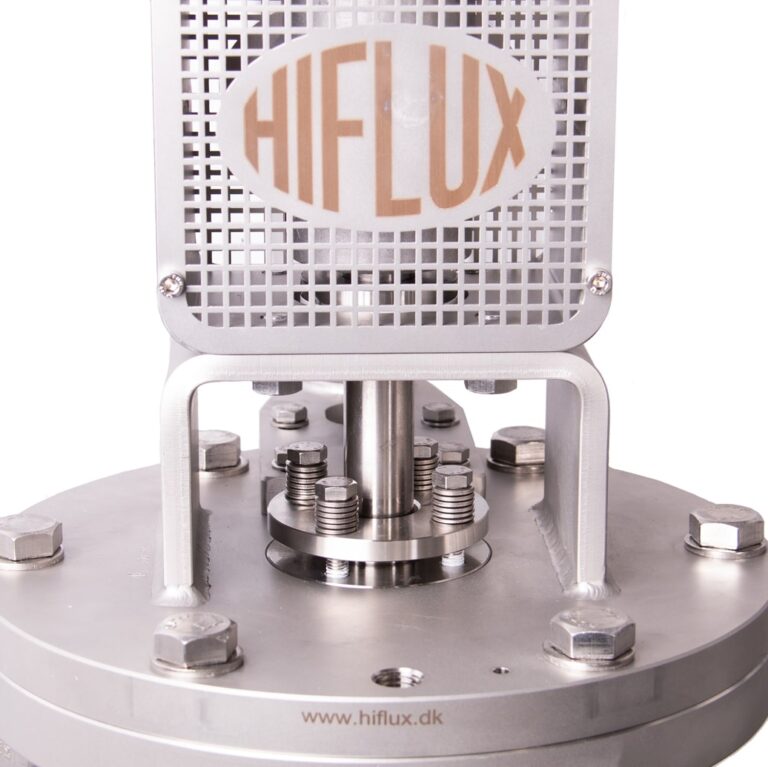

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems utilize cutting-edge technology to effectively remove all types of particulates from liquids used in baby food, safeguarding the quality and safety of the final product. The hygienic design of these systems adheres to the strictest food safety standards, minimizing the risk of contamination. This high level of filtration performance is essential for producing safe, high-quality baby food, directly impacting infants’ health and well-being.

Cost-Effective and Durable: A Smart Investment

Designed for durability and requiring minimal maintenance, HiFlux Filtration Systems offer a cost-effective solution for baby food production. The robust construction and self-cleaning functionality of these systems lead to reduced operational costs by minimizing the frequency of maintenance and part replacements. This results in a lower total cost of ownership and a quicker return on investment, supporting the industry’s goal of producing safe, high-quality baby food efficiently and sustainably.

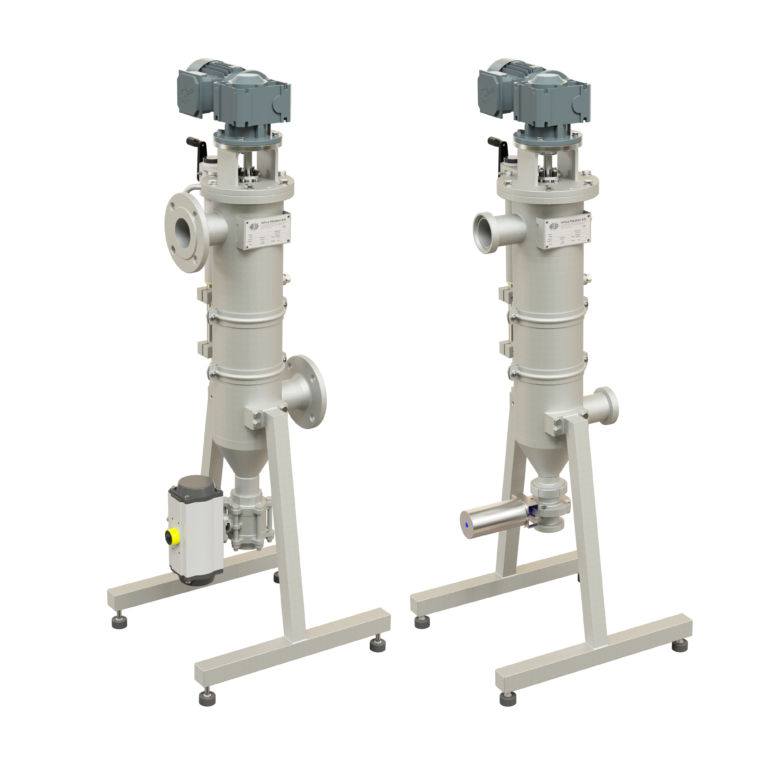

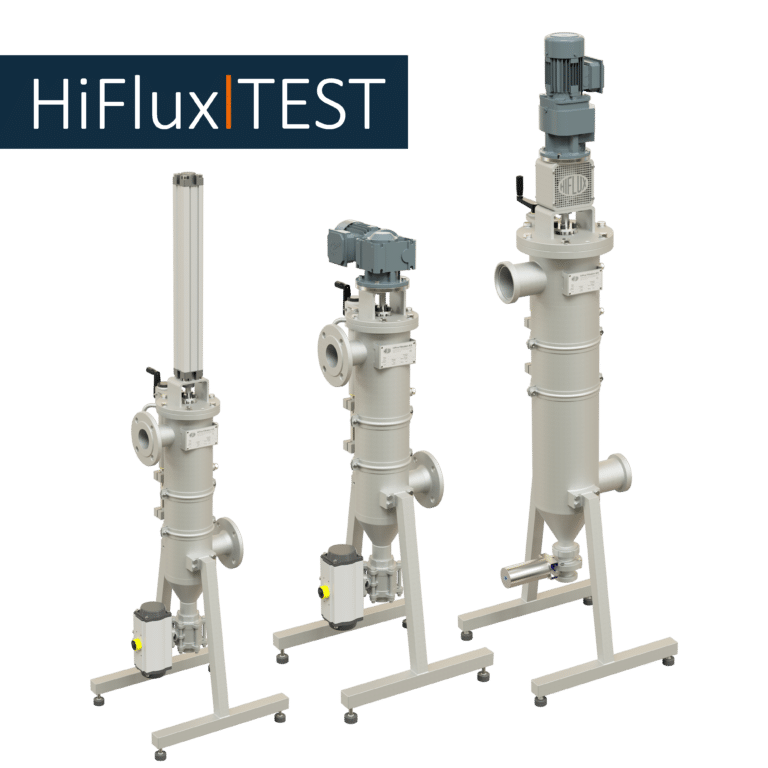

Flexibility and Future-Proofing: Adapting to Evolving Needs

The baby food industry is subject to continuous innovation and evolving regulatory requirements. HiFlux Filtration Systems are designed to be flexible and adaptable, enabling manufacturers to easily update their liquid processing operations to meet these changing demands. The modular design of HiFlux systems allows for straightforward scalability and updates, ensuring that manufacturers can maintain efficient and compliant operations, safeguarding their investments against future industry developments.

Conclusion: Enhancing Production with HiFlux

In conclusion, HiFlux Automatic Liquid Filtration Systems provide a crucial solution for the filtration of liquids in baby food production, addressing the critical needs for quality, efficiency, hygiene, and safety. By offering advanced, customizable filtration technology, HiFlux Filtration A/S enables manufacturers to optimize their liquid processing, achieving superior product quality and ensuring the safety of the most sensitive consumers—infants. This commitment to innovation, quality, and customer service positions HiFlux as a key partner for baby food manufacturers seeking to meet the stringent demands of a highly regulated and dynamic market landscape. The benefits of using the HiFlux auto-line filter in this process underscore the importance of reliable, efficient, and hygienic filtration in producing safe and nutritious baby food.