Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

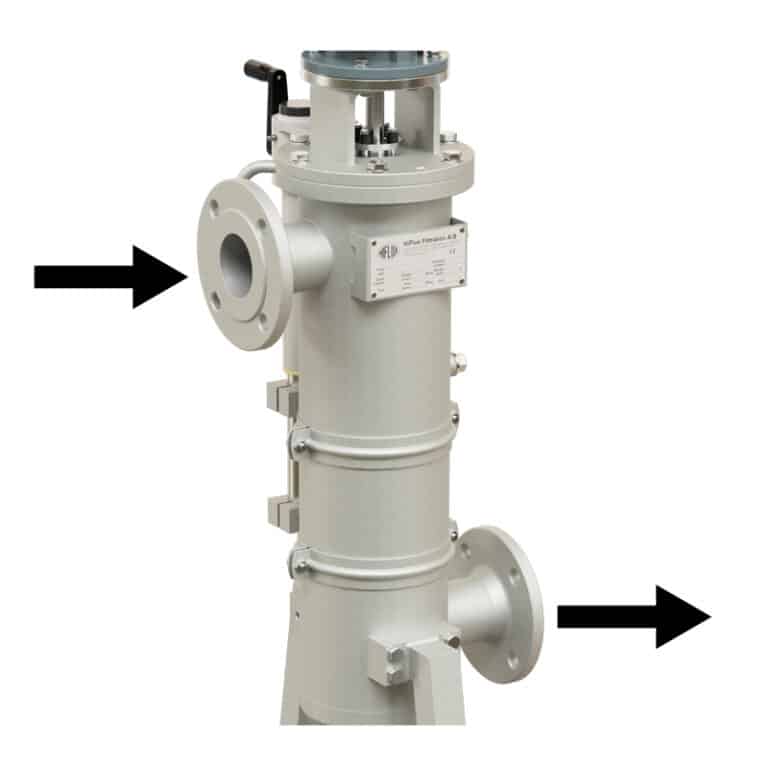

In the meticulous process of wax production, achieving a pristine liquid form free from particulate contamination is crucial for both product quality and process efficiency. HiFlux Automatic Liquid Filtration Systems play a pivotal role in this context, offering an innovative solution that excels in removing unwanted particles from wax. These systems are designed for continuous operation, minimizing downtime and enhancing the overall productivity of the production cycle. The self-cleaning technology embedded within ensures that the filtration process is seamless, contributing to a more efficient production flow, thus reducing operational costs while maintaining the integrity of the wax.

Customized Filtration Solutions: A Perfect Fit

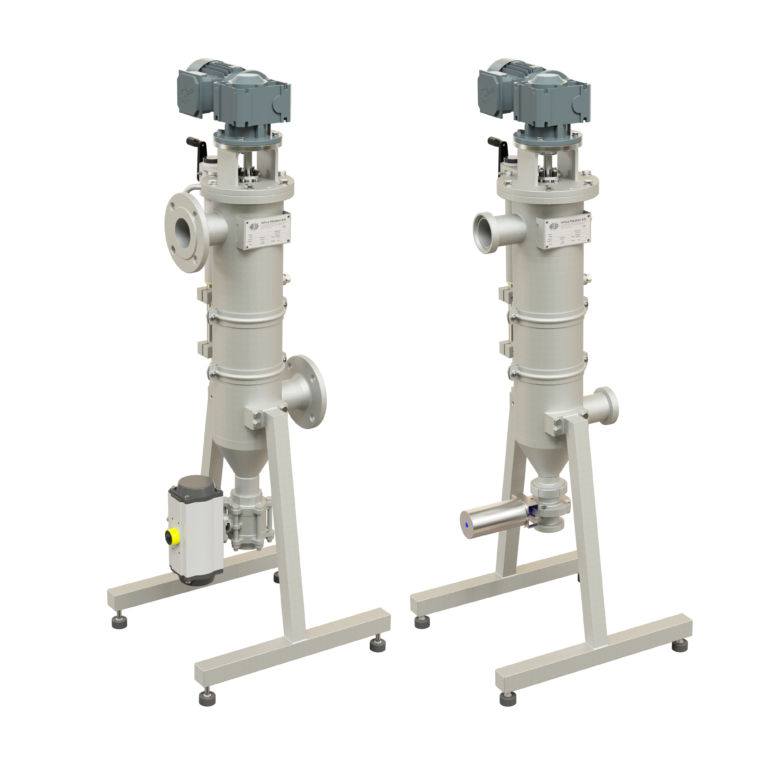

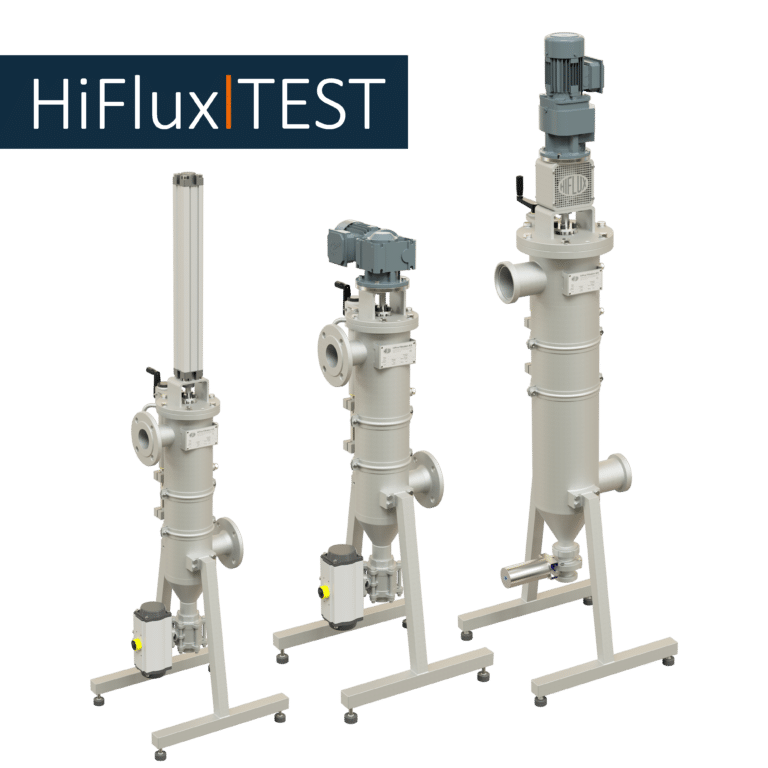

Recognizing the diverse nature of wax applications, HiFlux Filtration A/S prides itself on delivering customized filtration solutions that cater to the specific needs of the wax industry. Whether the challenge lies in processing high-viscosity waxes or selectively removing impurities while preserving essential components, HiFlux systems are engineered to integrate effortlessly into existing production setups. This tailored approach not only effectively addresses distinct filtration requirements but also significantly reduces the necessity for further capital investments, offering an ideal solution for any wax processing operation.

Advanced Filtration Technology: Ensuring Superior Quality

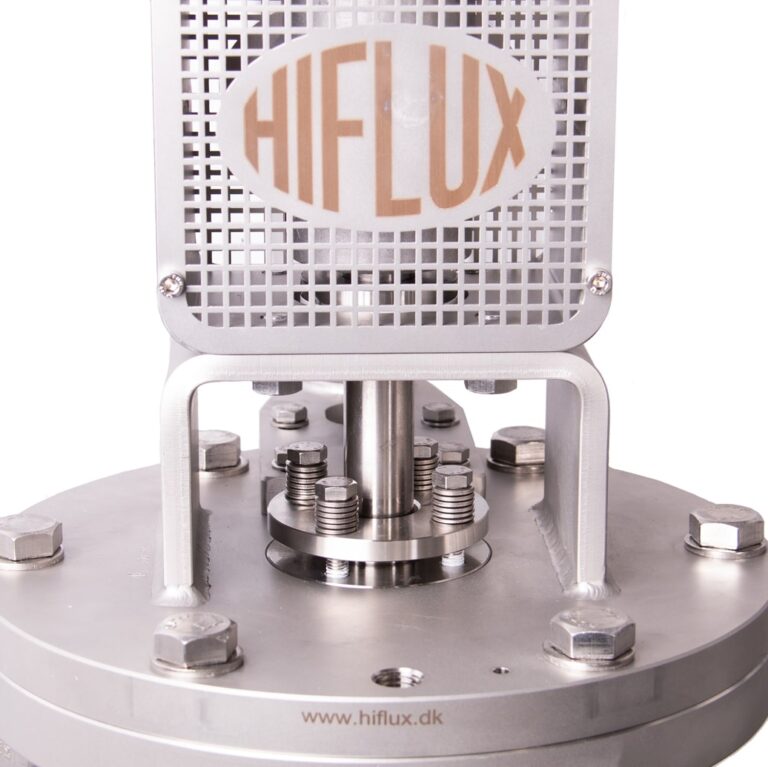

Employing state-of-the-art filtration technology, HiFlux Filtration Systems guarantee superior quality in wax production. The precision in removing oversize and harmful particles while preventing the entry of external contaminants ensures the production of a consistent, high-quality wax product. Continuous cleaning and scraping of the filter element maintain a steady filtration capacity, thereby eliminating the inconsistencies often seen with other filtration methods. This advanced technology ensures that the wax produced adheres to the highest quality standards demanded by various industries.

Cost-Effective and Durable: A Smart Investment

Opting for HiFlux Filtration Systems is a strategic choice for wax manufacturers seeking cost-efficient and durable solutions. The robust design and extended lifespan of the filter inserts lead to lower maintenance expenses. Simultaneously, the elimination of manual cleaning and the assurance of a continuous flow process drastically reduce operational costs. The long-term durability and efficiency of HiFlux Systems make them a prudent investment for businesses aiming at achieving sustainable growth and operational savings.

Flexibility and Future-Proofing: Adapting to Evolving Needs

HiFlux Filtration Systems are renowned for their modular design, offering unparalleled flexibility and the ability to future-proof operations. As the demands within the wax industry change, these systems can be effortlessly modified to meet new specifications, whether adjusting the filter insert type or accommodating different wax viscosities. This level of adaptability ensures that HiFlux Systems can evolve in tandem with industry requirements, solidifying their status as a flexible and future-proof investment for wax manufacturers.

Conclusion: Enhancing Production with HiFlux

HiFlux Automatic Liquid Filtration Systems stand at the forefront of filtration technology for the wax industry, delivering an all-encompassing solution that elevates both the product’s quality and the production process’s efficiency. By partnering with HiFlux, wax manufacturers can anticipate a system that not only fulfills their immediate filtration needs but is also equipped to adapt to future industry shifts, marking HiFlux as an invaluable ally in the quest for excellence and sustainability in wax production.