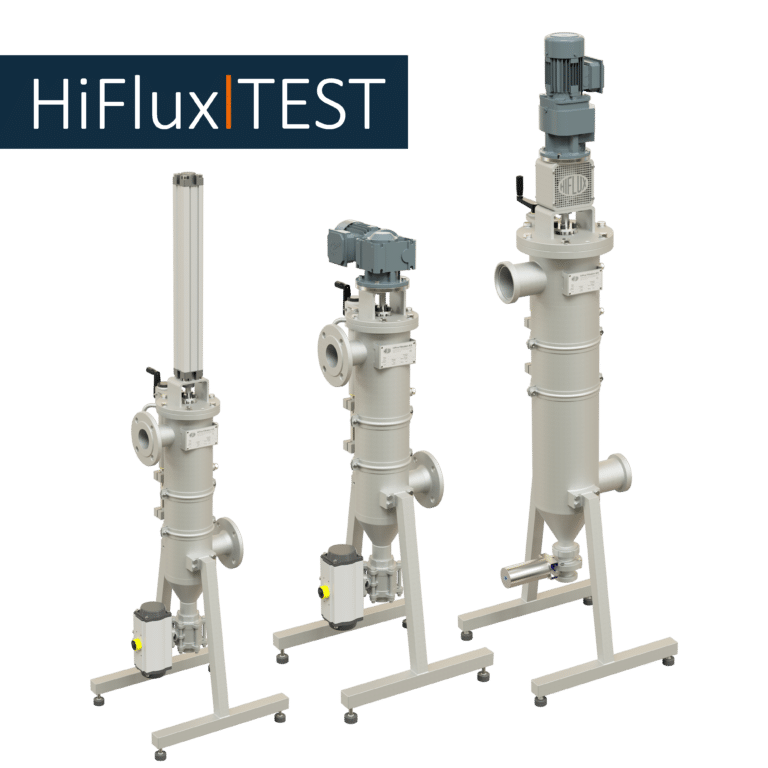

Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

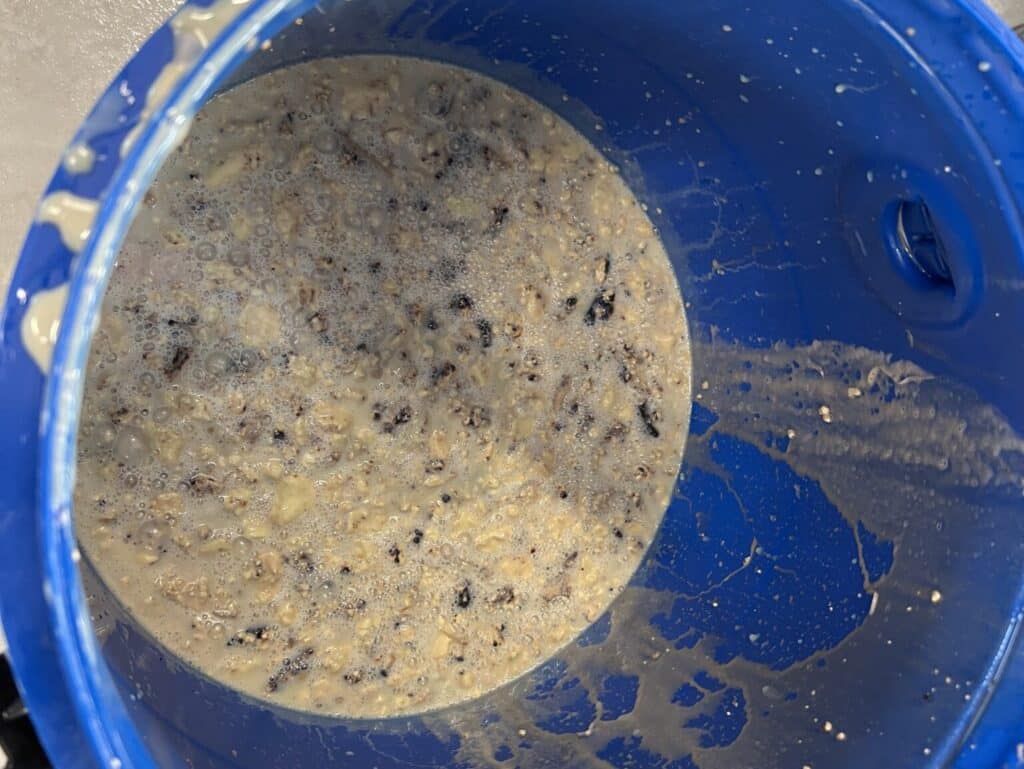

In the production of sweetened condensed milk, ensuring the removal of all particulates is essential to achieve a product that not only meets but exceeds consumer expectations for quality and taste. The HiFlux Automatic Liquid Filtration Systems, equipped with hygienic filters, are specifically designed for such delicate dairy processes. These systems significantly enhance the quality and efficiency of sweetened condensed milk production by utilizing self-cleaning technology, which reduces downtime and manual labor. This advanced approach ensures that the product remains consistently pure and of high quality, crucial for maintaining consumer trust and satisfaction.

Customized Filtration Solutions: A Perfect Fit

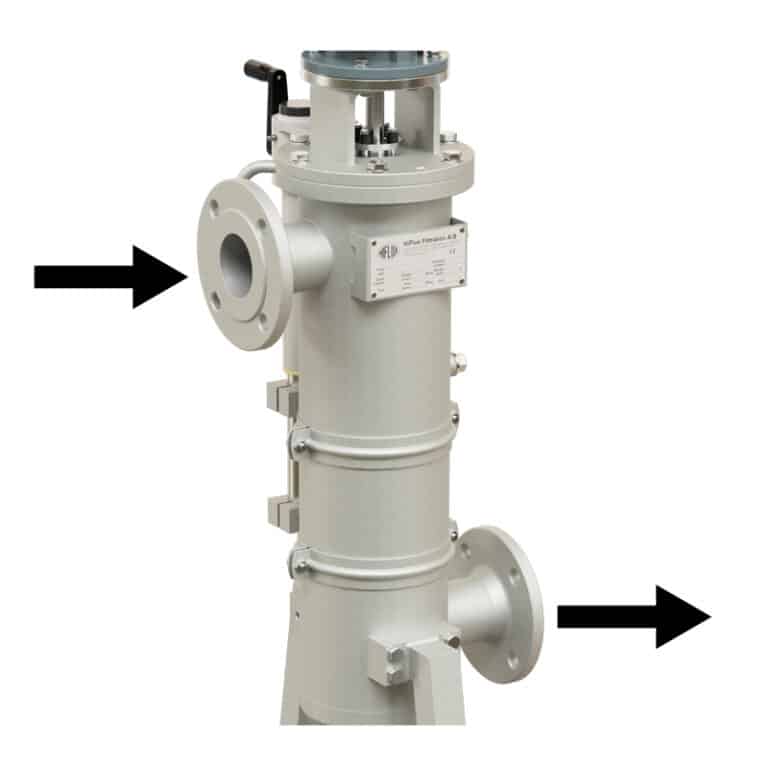

Recognizing the unique requirements of sweetened condensed milk production, including its high sugar content and viscosity, HiFlux Filtration A/S offers customized filtration solutions. These tailored systems are engineered to handle the specific challenges of filtering sweetened condensed milk, ensuring an optimal fit that maintains the product’s integrity while enhancing filtration efficiency. By seamlessly integrating into existing production lines, HiFlux systems minimize the need for extensive modifications, providing a cost-effective solution that maximizes product quality and production efficiency.

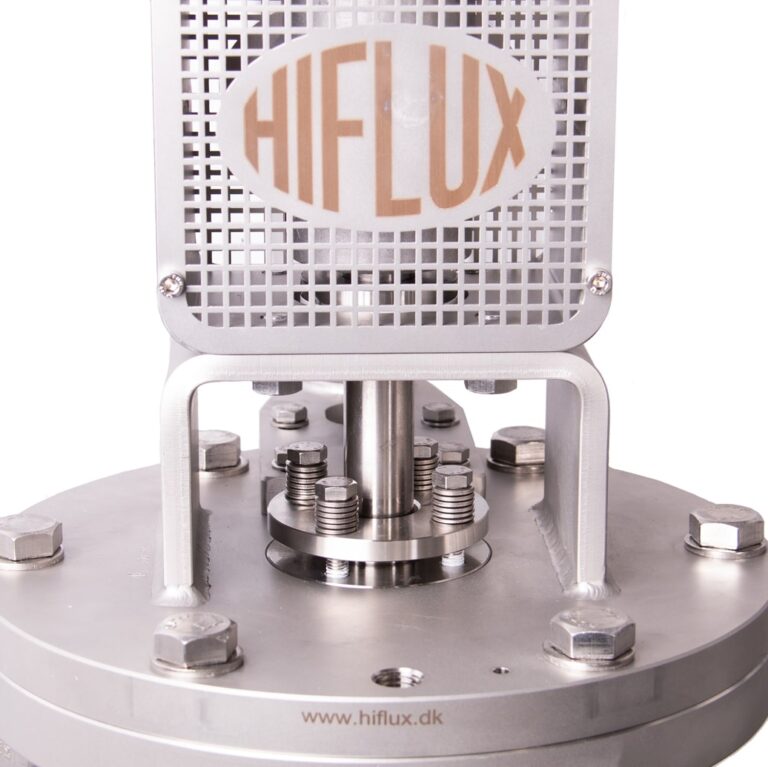

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems utilize cutting-edge technology to effectively remove particulates from sweetened condensed milk, safeguarding its smooth texture and uniform quality. The hygienic design of these filtration systems meets the highest standards of food safety, crucial for preventing contamination and ensuring the product’s wholesomeness. By maintaining the purity of sweetened condensed milk, HiFlux helps manufacturers deliver a product that is not only delicious but also adheres to stringent quality standards.

Cost-Effective and Durable: A Smart Investment

The durability and low maintenance requirements of HiFlux Filtration Systems present a smart investment for manufacturers of sweetened condensed milk. These systems are designed for longevity and efficient operation, reducing the frequency of maintenance and part replacements. This leads to significant operational cost savings, lower total cost of ownership, and a faster return on investment. The self-cleaning feature of HiFlux systems further enhances productivity by minimizing production interruptions, making it an economical choice for manufacturers.

Flexibility and Future-Proofing: Adapting to Evolving Needs

The food industry is ever-evolving, with consumer preferences and regulatory standards constantly changing. HiFlux Filtration Systems are built to adapt to these changes, offering manufacturers the flexibility to easily update and modify their filtration processes. The modular design of HiFlux systems ensures that sweetened condensed milk producers can efficiently respond to new challenges and market demands, securing their investment and maintaining a competitive edge in the market.

Conclusion: Enhancing Production with HiFlux

HiFlux Automatic Liquid Filtration Systems represent a comprehensive solution for enhancing the production of sweetened condensed milk. By offering advanced, customizable filtration technology that ensures product purity, quality, and safety, HiFlux Filtration A/S empowers manufacturers to optimize their processes. The benefits of using the hygienic auto-line filter from HiFlux include improved product quality, reduced operational costs, and increased efficiency, making it an indispensable tool for producers seeking to meet the high demands of the food industry and achieve lasting success.