Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

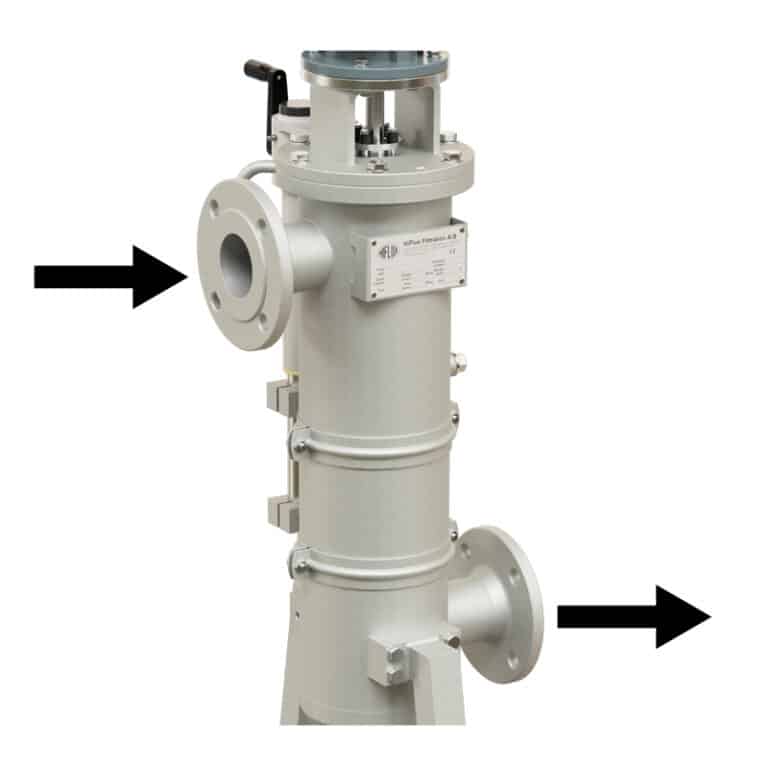

In the burgeoning industry of plant-based beverages, ensuring the highest quality of products like oat milk is essential for meeting consumer expectations and regulatory standards. HiFlux Automatic Liquid Filtration Systems, equipped with hygienic filters, are specifically designed to enhance the purity and quality of oat milk. These systems efficiently remove particulates, ensuring a smooth, consistent product that is crucial for consumer satisfaction. Leveraging self-cleaning technology, HiFlux systems significantly reduce downtime and manual labor, optimizing production efficiency and maintaining high-volume output essential in the competitive plant-based milk sector.

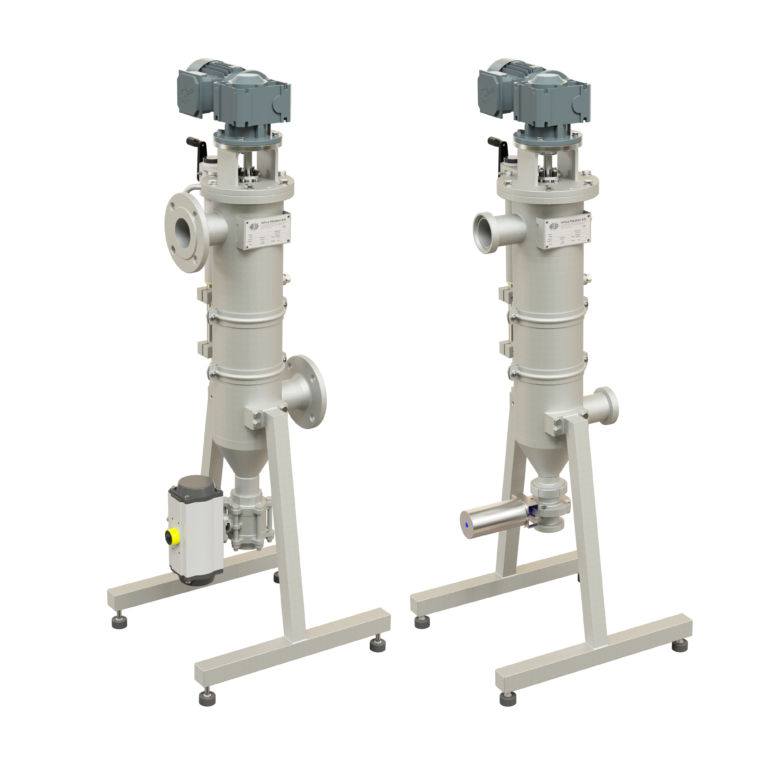

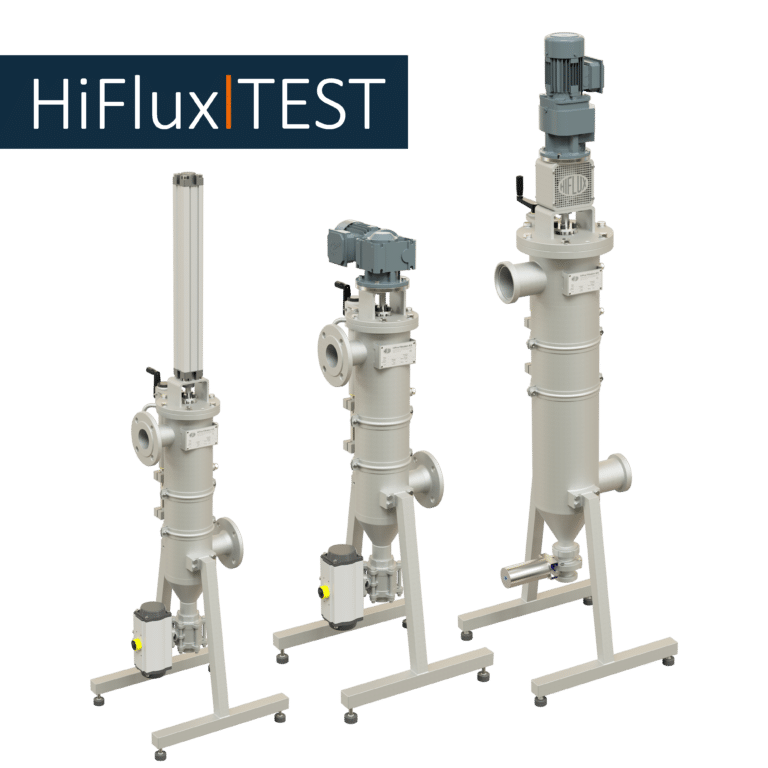

Customized Filtration Solutions: A Perfect Fit

Recognizing the unique challenges presented by the viscosity and particulate content of oat milk, HiFlux Filtration A/S offers customized filtration solutions tailored to this specific application. These systems are engineered to handle the nuances of oat milk filtration, ensuring optimal performance without compromising the product’s natural qualities. Integration into existing production lines is seamless, providing an efficient, cost-effective solution that minimizes the need for extensive retrofitting and reduces initial investment costs, making it a perfect fit for oat milk producers looking to enhance their process.

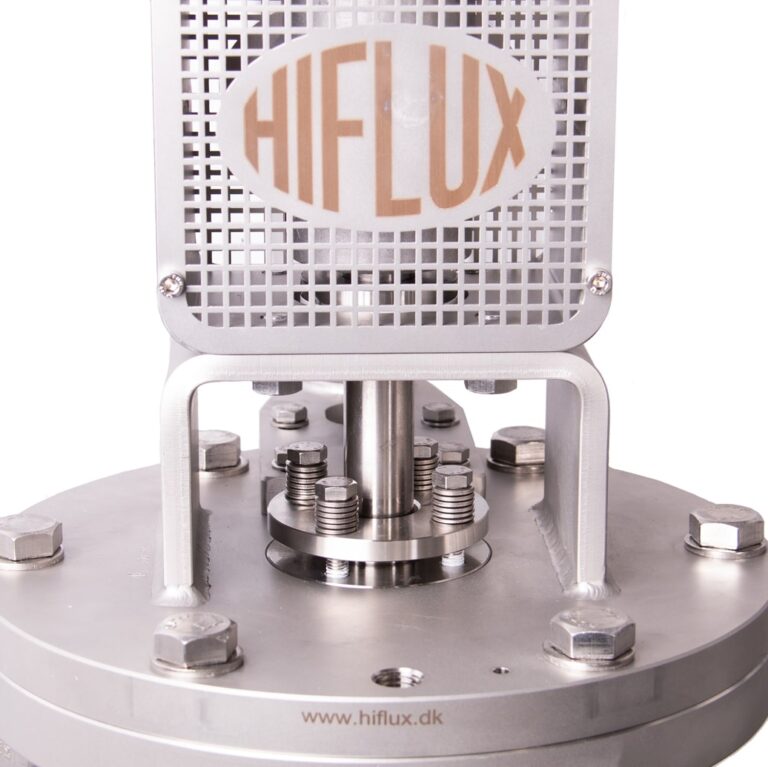

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems utilize cutting-edge technology to remove all types of particulates from oat milk, including fine solids that could affect the product’s texture and appearance. The hygienic design of these systems ensures compliance with the strictest food safety standards, reducing the risk of contamination and spoilage. This level of filtration precision is critical for producing high-quality oat milk, helping manufacturers achieve a product that is not only safe and clean but also meets the high expectations of health-conscious consumers.

Cost-Effective and Durable: A Smart Investment

The robust construction and innovative self-cleaning mechanism of HiFlux Filtration Systems translate to durability and low maintenance, offering oat milk producers a cost-effective solution for their filtration needs. These features reduce the frequency of part replacements and labor costs associated with filter maintenance, leading to lower operational costs. For oat milk producers, this means a lower total cost of ownership and a quicker return on investment, aligning with the industry’s goals of maximizing efficiency while ensuring product quality.

Flexibility and Future-Proofing: Adapting to Evolving Needs

As consumer preferences shift and demand for plant-based milks continues to grow, the ability to adapt to changing market conditions is essential. HiFlux Filtration Systems are designed with flexibility and scalability in mind, allowing oat milk producers to easily adjust their filtration processes to accommodate new formulations or increased production volumes. This modular design ensures that manufacturers can future-proof their operations, maintaining efficiency and compliance without the need for significant reinvestment.

Conclusion: Enhancing Production with HiFlux

In conclusion, HiFlux Automatic Liquid Filtration Systems offer an essential solution for the filtration of oat milk, addressing the industry’s critical needs for quality, efficiency, and hygiene. By offering advanced, customizable filtration technology, HiFlux Filtration A/S enables oat milk manufacturers to optimize their production processes, ensuring the production of superior plant-based milk products. This commitment to innovation, quality, and customer service positions HiFlux as a key partner for producers in the rapidly expanding plant-based milk industry, helping them achieve their ope