Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems for Nozzle Protection

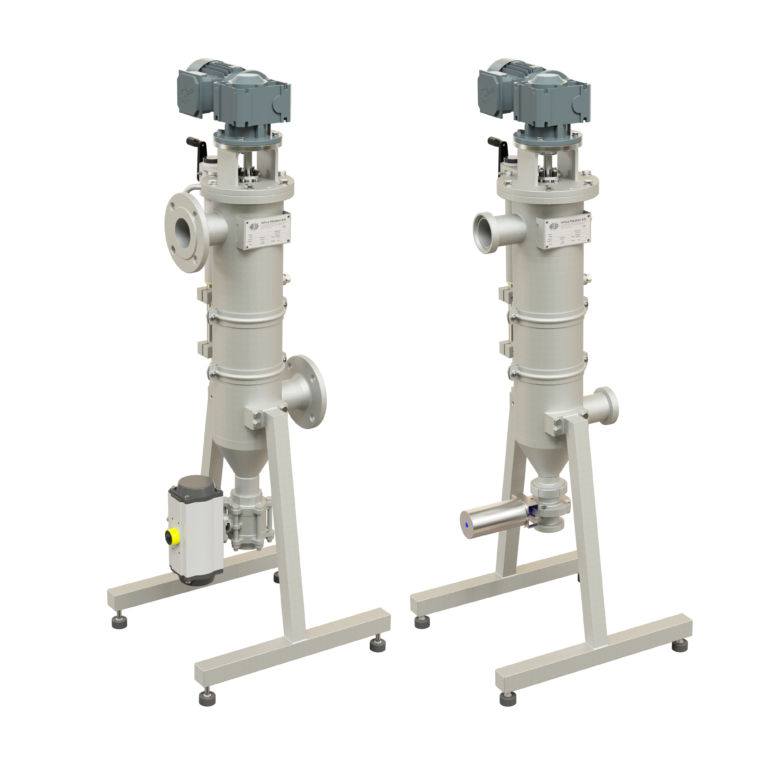

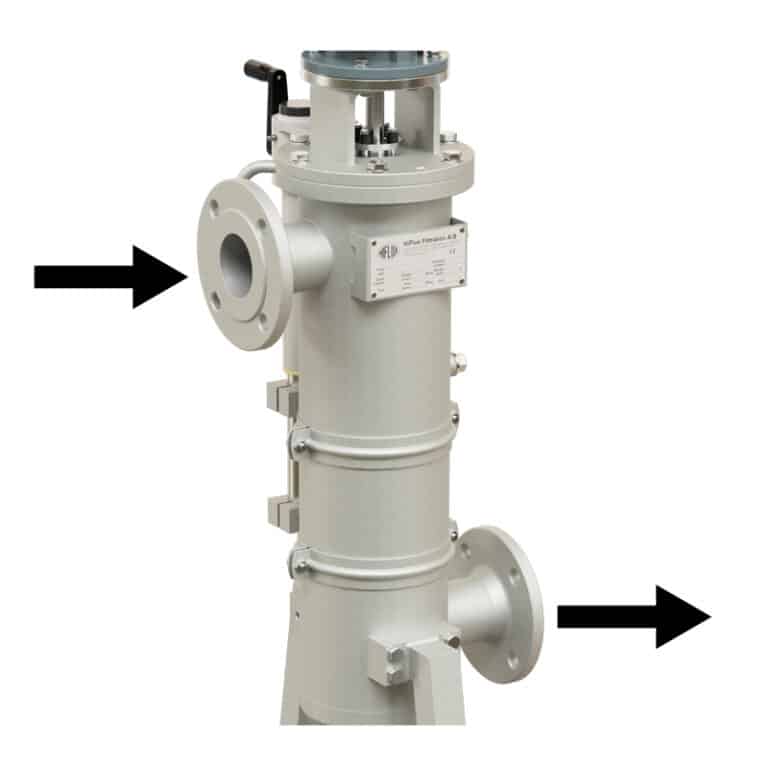

In the paint industry, nozzle clogging can significantly impede production efficiency and compromise the quality of spray applications. HiFlux Automatic Liquid Filtration Systems are specifically designed to tackle this challenge by removing particles that could lead to nozzle blockages. These advanced systems ensure a continuous and smooth operation, significantly reducing the risk of downtime and enhancing overall production efficiency. The self-cleaning feature of the HiFlux systems minimizes maintenance requirements, allowing for uninterrupted paint processing and application.

Customized Filtration Solutions: A Perfect Fit for Nozzle Protection

Recognizing the critical role of nozzle protection in paint applications, HiFlux Filtration A/S provides customized filtration solutions tailored to the unique requirements of the paint industry. These solutions are engineered to prevent particles from clogging nozzles, ensuring a consistent and high-quality paint application. By closely working with clients, HiFlux systems are designed to integrate seamlessly into existing paint production lines, offering a tailored approach that addresses the specific challenges of nozzle protection without necessitating significant additional investments.

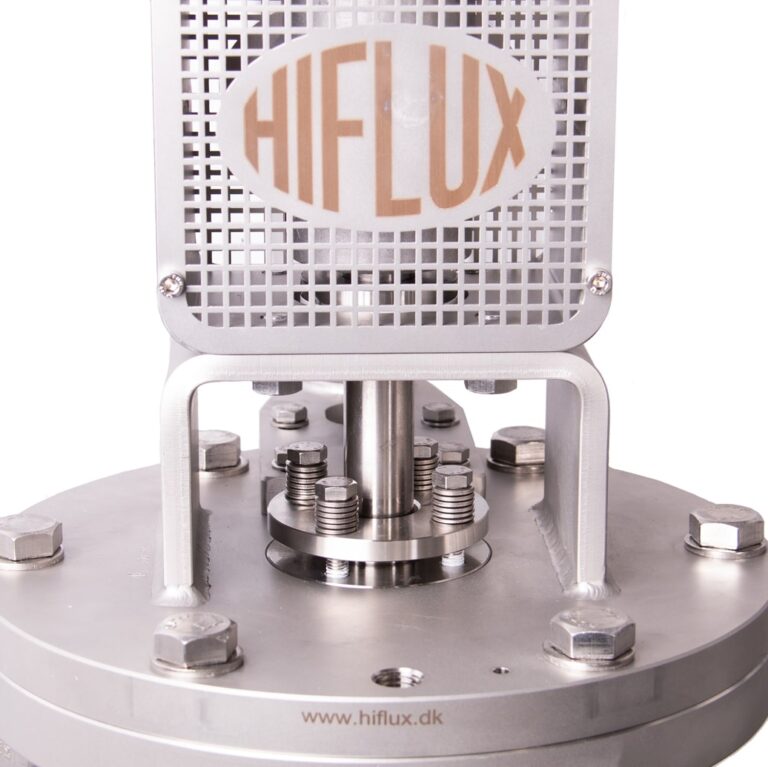

Advanced Filtration Technology: Ensuring Superior Nozzle Performance

The advanced filtration technology of HiFlux Systems plays a pivotal role in maintaining superior nozzle performance. By effectively removing particles that could cause blockages, these systems ensure a consistent paint flow and spray pattern, which is crucial for achieving a high-quality finish. The precision and efficiency of HiFlux’s filtration technology mean that paint manufacturers can rely on their nozzles to perform optimally, reducing the need for rework and ensuring that the final product meets the industry’s high standards.

Cost-Effective and Durable: A Smart Investment for Nozzle Longevity

Investing in HiFlux Filtration Systems for nozzle protection is a cost-effective choice for paint manufacturers. The durability and efficiency of these systems not only extend the lifespan of spray nozzles but also contribute to significant cost savings by reducing the frequency of nozzle replacements and maintenance. The robust design and long service life of the HiFlux filter elements further underscore the systems’ value as a smart investment, offering long-term financial benefits and operational reliability.

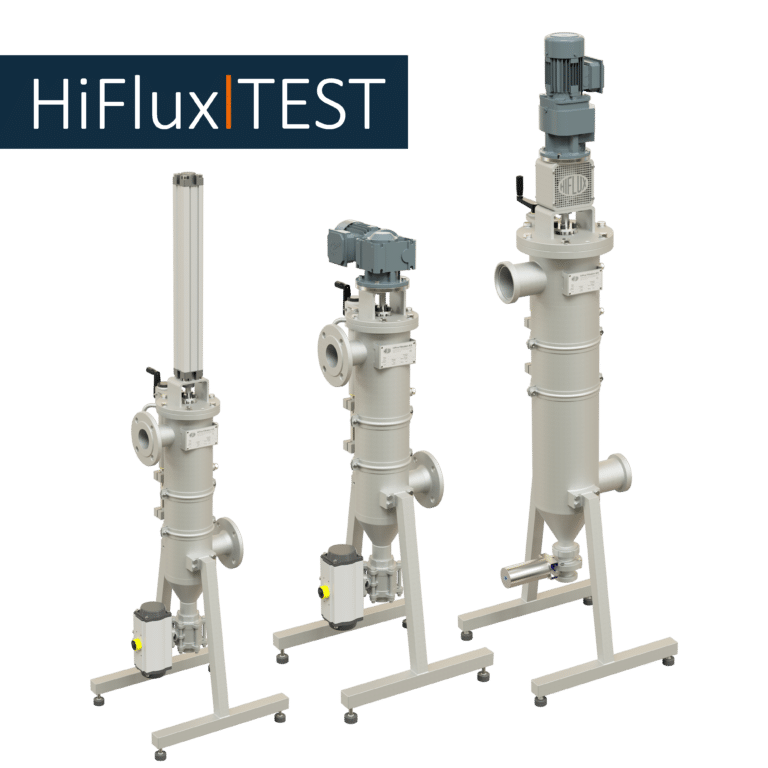

Flexibility and Future-Proofing: Keeping Pace with Industry Advances

The paint industry is continually evolving, with advancements in paint formulations and application techniques. HiFlux Filtration Systems are designed with flexibility in mind, enabling easy adaptation to new requirements and ensuring that nozzle protection remains effective even as industry demands change. This future-proofing capability ensures that paint manufacturers can maintain a competitive edge, adapting quickly to new challenges and opportunities without the need for significant reinvestment in filtration technology.

Conclusion: Enhancing Production with HiFlux for Optimal Nozzle Protection

HiFlux Automatic Liquid Filtration Systems offer an unparalleled solution for nozzle protection in the paint industry, enhancing both the quality of paint applications and the efficiency of production processes. By preventing nozzle clogging and ensuring consistent paint flow, HiFlux systems help manufacturers achieve superior product quality and operational excellence. Choosing HiFlux for nozzle protection means investing in a system that not only meets the current needs of the paint industry but is also equipped to handle future challenges, making it an invaluable asset for any paint manufacturing operation.