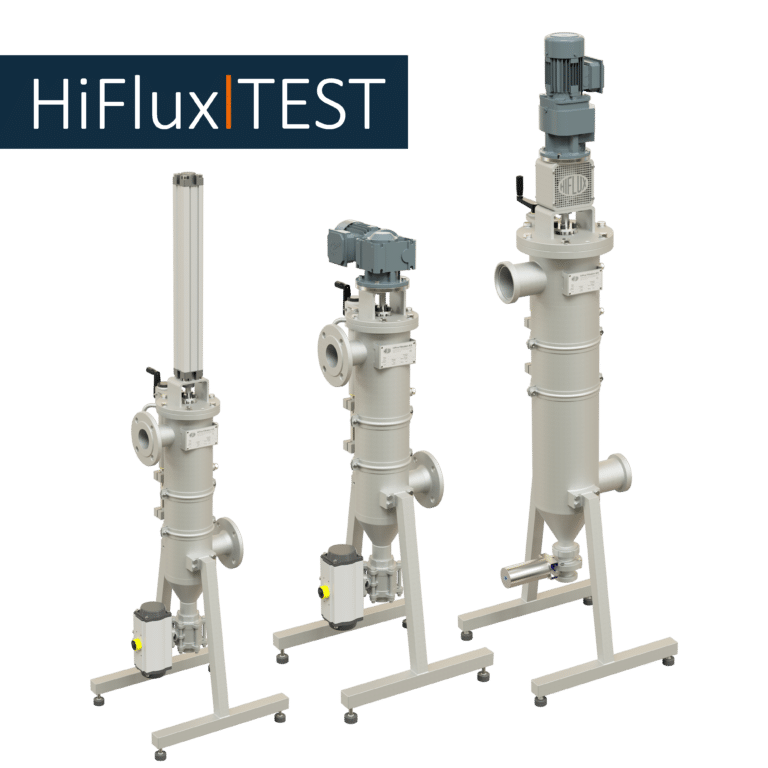

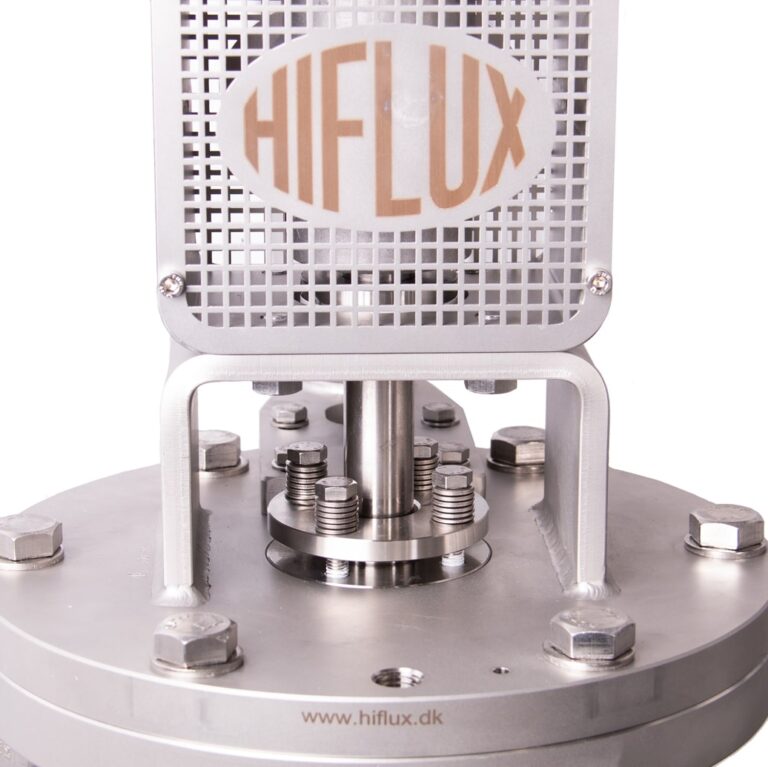

Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

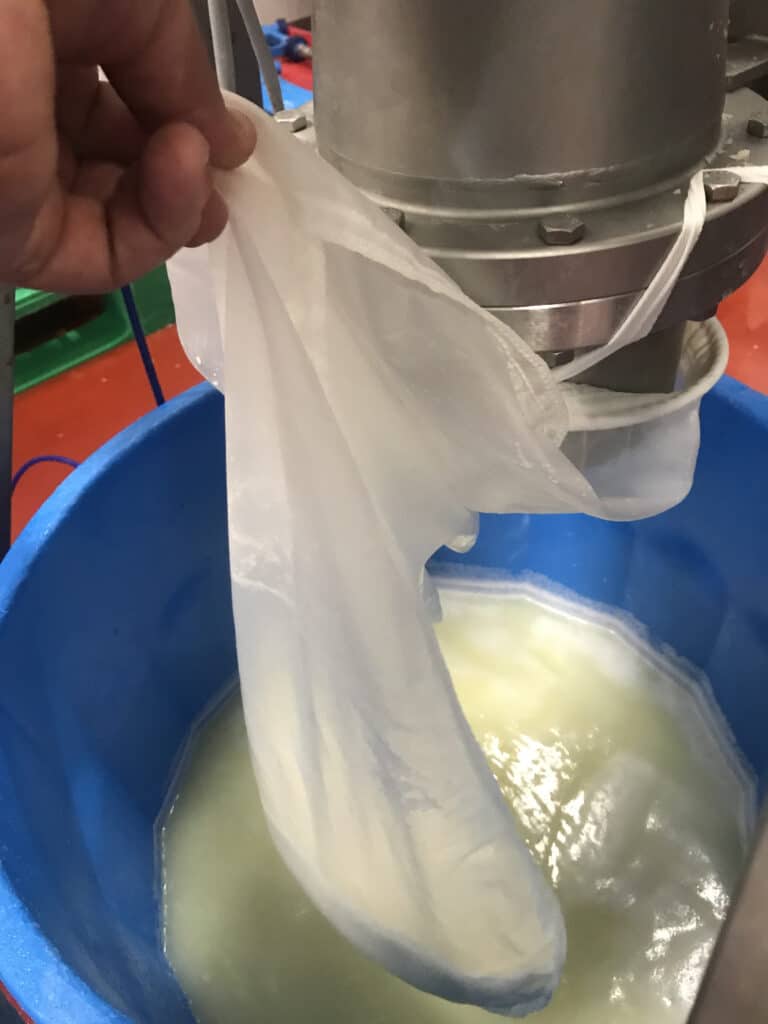

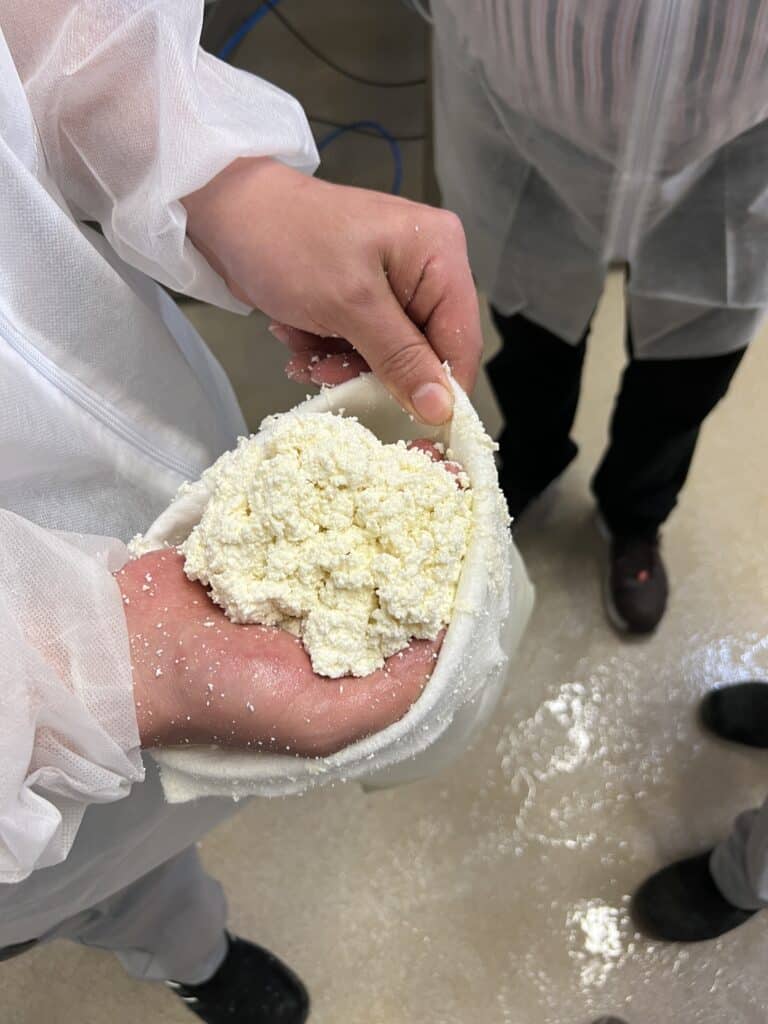

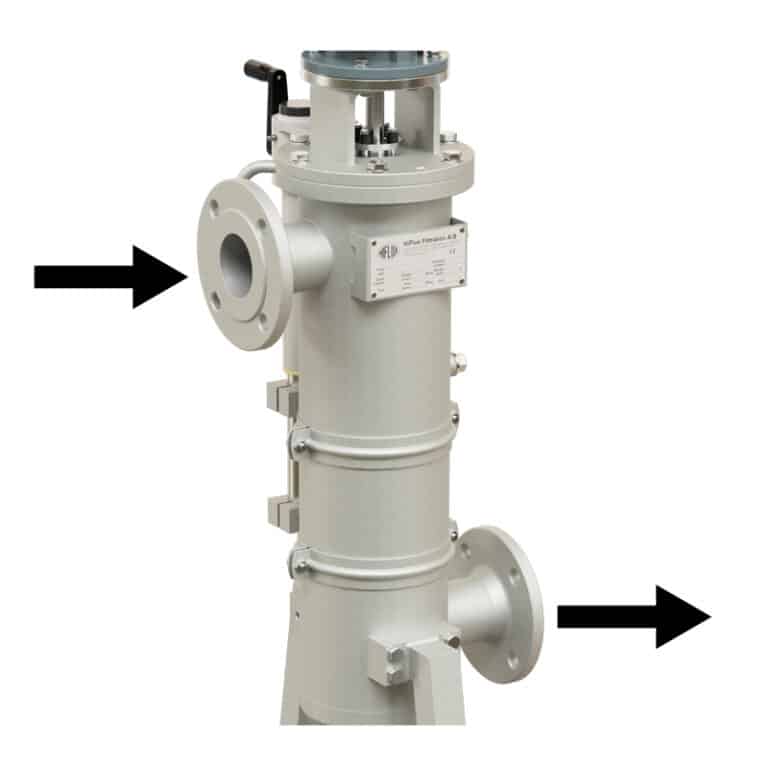

In the dynamic landscape of the dairy industry, cheese whey processing stands out as a crucial operation where the purity and quality of whey directly influence the value and usability of this by-product. HiFlux Automatic Liquid Filtration Systems, equipped with state-of-the-art hygienic filters, are expertly designed to remove particulates from cheese whey, enhancing both product quality and processing efficiency. These systems utilize self-cleaning technology to significantly reduce downtime and labor costs, ensuring that whey is processed under the highest hygiene standards, essential for producing high-quality whey protein concentrates, isolates, and other whey-based products.

Customized Filtration Solutions: A Perfect Fit

Given the varied applications and processing requirements of cheese whey, HiFlux Filtration A/S offers customized filtration solutions tailored to meet these specific needs. Whether for whey destined for food products, nutritional supplements, or other applications, HiFlux systems are engineered to handle the unique properties of whey, ensuring efficient and effective particulate removal. This customization allows for seamless integration into existing whey processing lines, offering an optimal solution that minimizes the need for significant modifications and reduces initial investment costs.

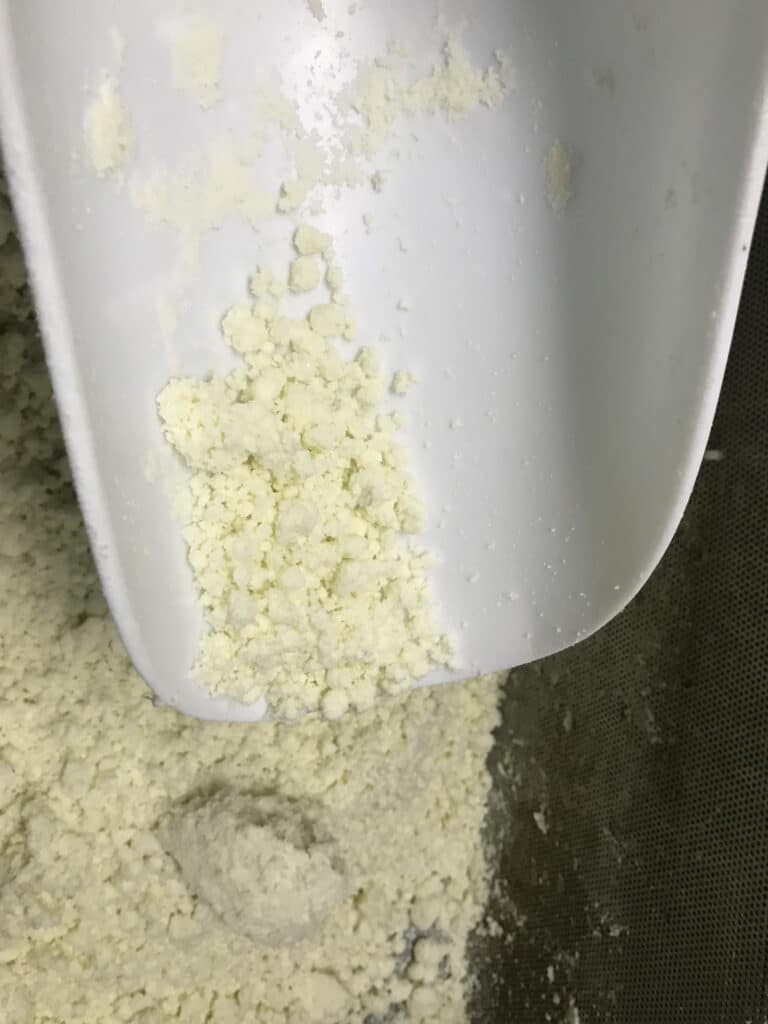

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems leverage advanced technology to effectively filter out particulates from cheese whey, ensuring the removal of all unwanted materials while maintaining the nutritional and functional properties of the whey. The hygienic design of these systems adheres to the strictest food safety standards, minimizing the risk of contamination and spoilage. This high level of filtration performance is crucial for maintaining the quality and safety of whey products, helping manufacturers meet regulatory requirements and consumer expectations.

Cost-Effective and Durable: A Smart Investment

Designed for durability and low maintenance, HiFlux Filtration Systems offer a cost-effective solution for cheese whey processing. The robust construction and self-cleaning functionality of these systems lead to reduced operational costs by minimizing the frequency of maintenance and part replacements. For manufacturers, this translates into a lower total cost of ownership and a quicker return on investment, aligning with the industry’s goal of maximizing efficiency while ensuring the highest quality of whey products.

Flexibility and Future-Proofing: Adapting to Evolving Needs

The dairy industry is continually evolving, with new product formulations and stricter hygiene standards. HiFlux Filtration Systems are designed to be flexible and adaptable, enabling manufacturers to easily modify their whey processing operations to meet these changing demands. The modular design of HiFlux systems allows for straightforward updates and scalability, ensuring that manufacturers can adapt their operations efficiently, securing their investments against future industry developments.

Conclusion: Enhancing Production with HiFlux

In conclusion, HiFlux Automatic Liquid Filtration Systems provide an essential solution for the filtration of cheese whey, addressing the critical needs for quality, efficiency, and hygiene in dairy processing. By offering advanced, customizable filtration technology, HiFlux Filtration A/S enables manufacturers to optimize their whey processing, achieving superior product quality and maximizing the value of cheese whey. This commitment to innovation, quality, and customer service positions HiFlux as a key partner in the dairy industry, helping manufacturers meet their operational and quality goals.