Maximizing Quality and Efficiency with HiFlux Automatic Liquid Filtration Systems

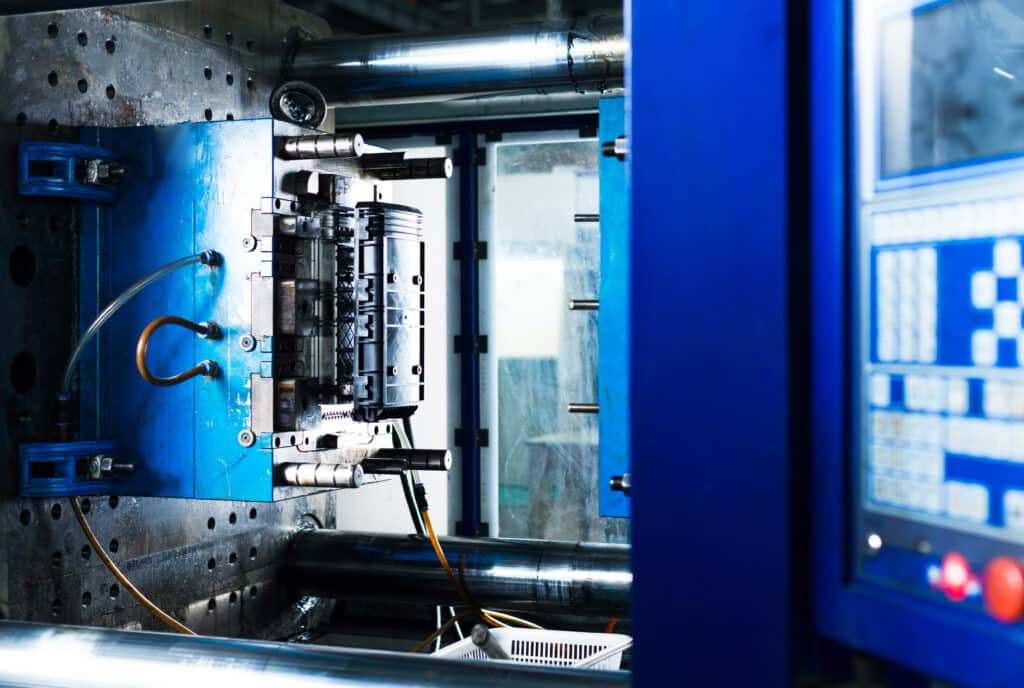

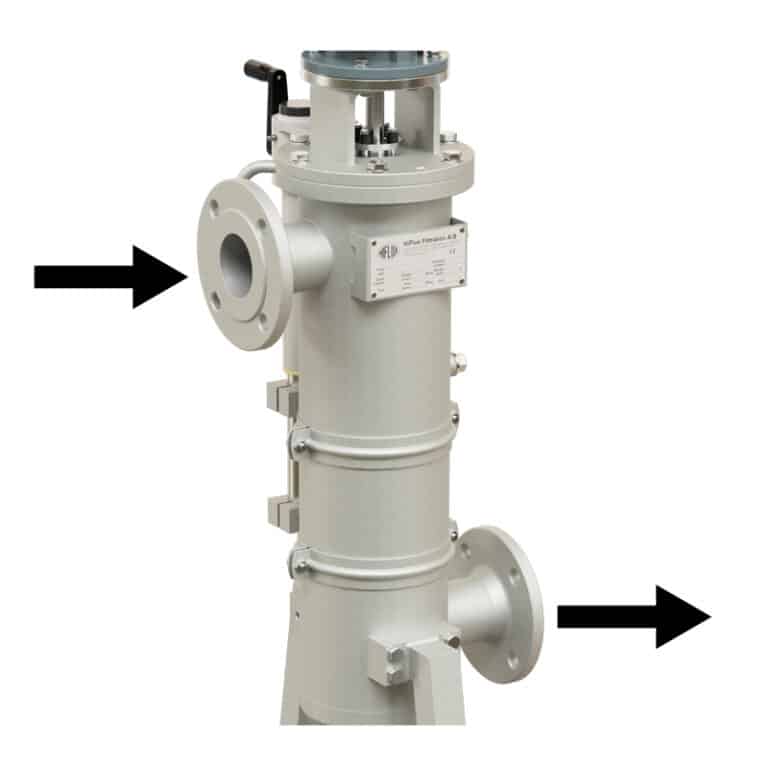

In the demanding environment of plastic extrusion and molding, the quality of cooling water is crucial for both the efficiency of the process and the quality of the end product. HiFlux Automatic Liquid Filtration Systems play a vital role in maintaining the purity of cooling water by efficiently removing particles, thus preventing blockages and ensuring a steady flow. This leads to a significant reduction in downtime and maintenance costs, allowing for uninterrupted operation and higher productivity levels. The self-cleaning feature of these systems minimizes manual intervention, further enhancing operational efficiency.

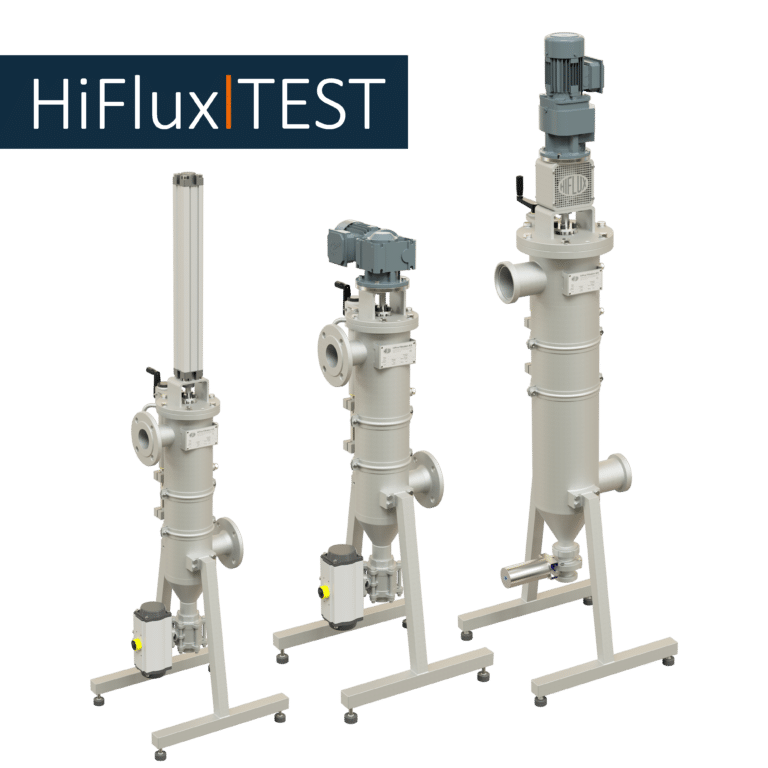

Customized Filtration Solutions: A Perfect Fit

Recognizing the diverse needs of the plastic extrusion and molding industry, HiFlux Filtration A/S offers tailored filtration solutions designed to meet the specific requirements of cooling water systems. Whether it’s dealing with high loads of particulate matter or accommodating varying flow rates, HiFlux systems are engineered to integrate seamlessly into existing operations. This customization ensures that the cooling water is maintained at optimal quality, preventing equipment wear and tear, and extending the lifespan of molding forms and extruders.

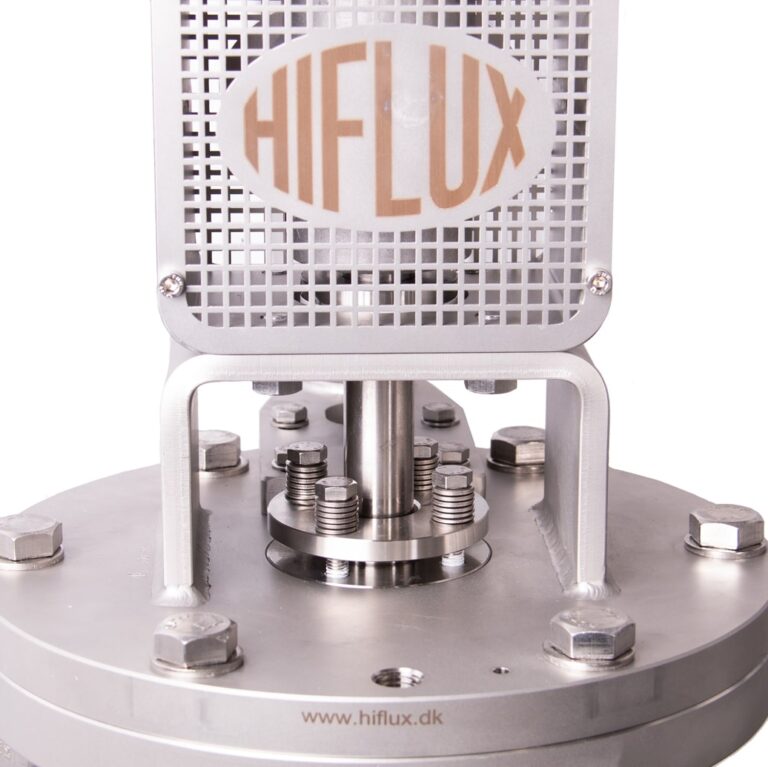

Advanced Filtration Technology: Ensuring Superior Quality

HiFlux Filtration Systems utilize cutting-edge technology to provide superior filtration for cooling water in plastic extrusion and molding processes. By efficiently removing particles and preventing the buildup of contaminants, these systems ensure the thermal efficiency of cooling systems is maintained, directly impacting the quality of the molded or extruded plastics. Consistent cooling water quality leads to fewer defects, higher product quality, and reduced wastage, contributing significantly to the overall efficiency of the manufacturing process.

Cost-Effective and Durable: A Smart Investment

The robust design and durability of HiFlux Filtration Systems make them a cost-effective investment for the plastic extrusion and molding industry. The long service life and low maintenance requirements of the system reduce the total cost of ownership. Additionally, by safeguarding against equipment damage and process interruptions, HiFlux systems contribute to significant operational savings over time. Their reliability and efficiency make them an indispensable asset for manufacturers looking to optimize their cooling water processes.

Flexibility and Future-Proofing: Adapting to Evolving Needs

HiFlux Filtration Systems are designed with flexibility in mind, accommodating changes in production scale, process requirements, or cooling water conditions. Their modular design allows for easy adaptation and upgrades, ensuring that the filtration system can evolve alongside the plastic extrusion and molding industry. This future-proofing capability makes HiFlux a valuable partner for businesses aiming to stay ahead in a competitive and rapidly changing market.

Conclusion: Enhancing Production with HiFlux

For the plastic extrusion and molding industry, HiFlux Automatic Liquid Filtration Systems offer a comprehensive solution for maintaining the purity and efficiency of cooling water. By leveraging the advanced technology, customized solutions, and the durable, cost-effective design of HiFlux systems, manufacturers can significantly enhance their production processes. The flexibility and adaptability of these systems ensure they remain a valuable asset, capable of meeting both current and future cooling water filtration needs, driving sustainability, and efficiency in plastic manufacturing processes.