HiFlux TS Strainer Filters for pressure systems are used where there is a need for efficient fine filtration with a large dirt capacity and low differential pressure.

The filters can be used as suction or pressure filters and have a simple and safe closure system which makes the cleaning time short, thereby maximizing the time the filters are in operation.

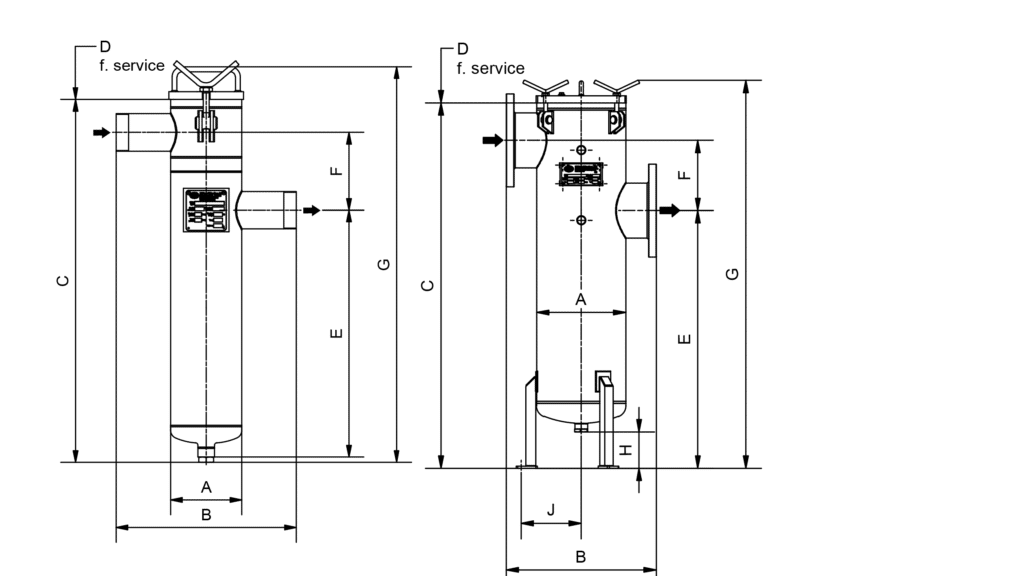

A compact design and a maximum built-in filter surface ensure the best possible flow and consequently a small differential pressure, long intervals between cleaning of the strainer element and low energy consumption.

The filter consists of two main elements

- The filter housing, which is designed in accordance with current pressure vessel norms, in welded carbon steel or stainless acid-proof EN 1.4404 steel.

- The strainer with its maximized surface can withstand a differential pres-sure of 2 bar. The filter mesh is made of stainless steel in a hard-wearing weave. The strainer is designed in such a way that it is easy to disassemble for efficient cleaning. This also ensures a quick and easy change of filtration degree if required.

In the standard version the direction of flow is from inside and out through the filter insert. The dirt is retained in the filter strainer, which can be lifted out and cleaned with ease. It is possible to use the strainer filter with reverse flow. This means that the dirt is retained on the outside of the strainer and it is possible to remove the sludge from the filter by fitting a valve into the drain.

The filter can also be fitted with a magnetic system which makes it possible to retain magnetic particles. The magnetic insert is designed as an integrate part of the strainer insert for simple and fast handling in connection with cleaning.

The TS 3, TS 4 and TS 5 filters are fitted with two G1/2B outlets for connecting pressure gauges or a differential pressure indicator, if required.

Special versions in accordance with the customers’ specifications. This typically includes different choice of materials, type/size/location of connections, different pressure limits and/or temperature levels. All TS filters are standardly produced according to the pressure equipment directive 2014/68/EU article 4, section 3. The filters can be delivered with approval according to category I, II, III or IV.

For other options see also HiFlux LSS, HiFlux Micro Line 1050, HiFlux Micro Line 1050 SS and TS 6 -8.