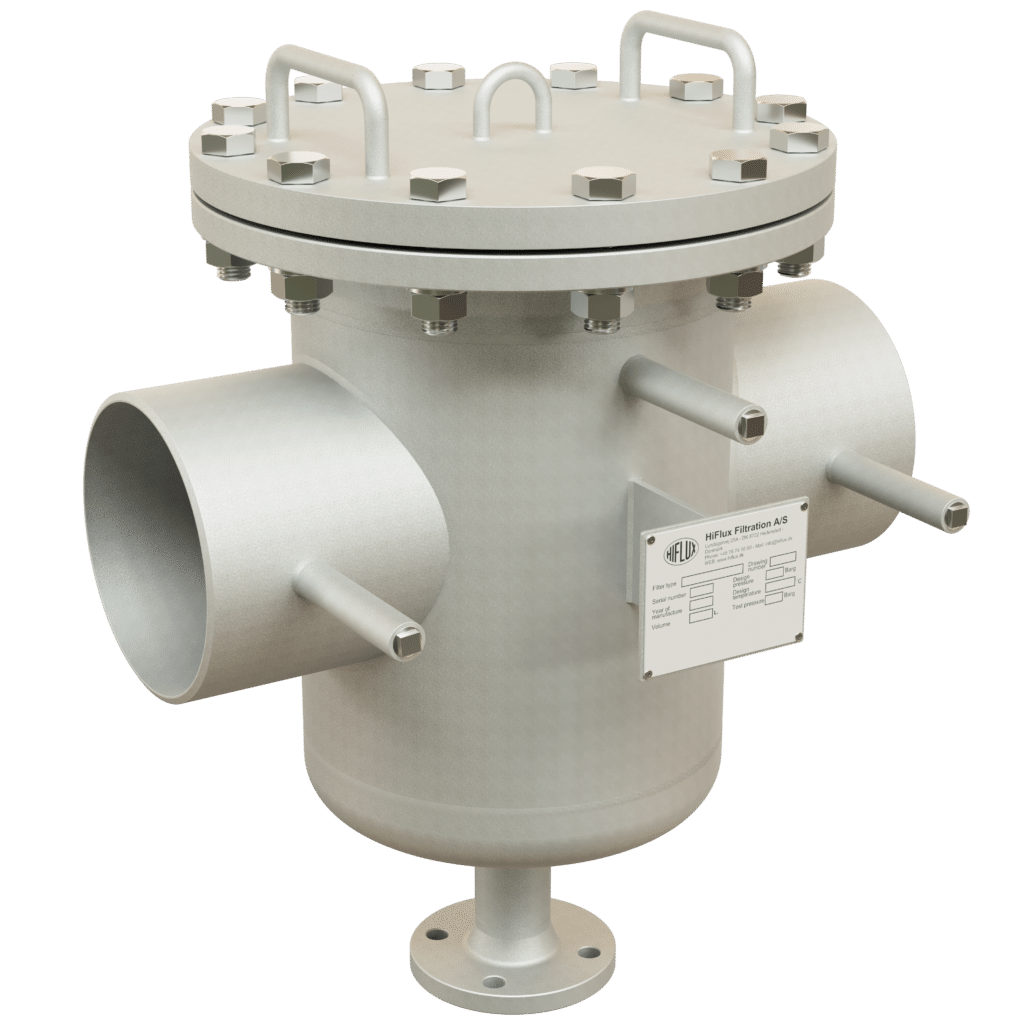

HiFlux LSS1 Strainer Filters have been developed especially for use as protection filters for distribution and transmission systems in the energy sector.

The filters are used to protect pumps, heat exchangers, valves, boilers, pipes, etc.

In the filter design importance has been attached to optimising the flow conditions in such a way that maximum capacity is achieved with minimum loss of pressure throughout the period of operation. This has been achieved by means of a special filter strainer design which ensures that retained dirt is not kept in or on the filter surface, but is deposited either in the filter strainer or the filter housing. This leaves an active and open filter area throughout the period of operation, resulting in extremely low energy consumption and longer intervals between the need for manual cleaning.

The energy consumption for operation of the LSS 1 filter is typically 70 to 80% lower than conventional filters and dirt collectors. In a simple cycle of a DN 100 size this can lead to savings of up to 22,000 kWh in reduced energy consumption.

The filter is supplied in two standard versions, with the dirt either being retained in the strainer insert: Type LSS 1, or deposited in the filter housing: Type LSS 1 RF. The version with depositing in the filter housing makes it possible to remove the sludge through a drain in the bottom without interrupting the flow through the filter.

The type with sludge removal in the bottom is often used in systems with high sludge loads. Sludge removal may be carried out via a valve lock, there-by preventing large pressure surges in the system.

The filter strainer has been developed to resist powerful impacts from large foreign bodies which could be carried through the system at high speed. LSS 1 and LSS 1 RF are supplied as standard with 1 mm, 3 mm, 6 mm and 8 mm filtration. LSS 1 RF can also be supplied with 0.5 mm filtration.

The air vent is built into the side of the filter housing and makes it possible to connect it to a vent circuit which does not need to be disassembled when the filter is cleaned as the cover can be removed freely.

Special versions with regard to building-in, capacity, temperature and pressure can be made in co-operation with our technical department.

All LSS/LSF filters are standardly produced according to the pressure equipment directive 2014/68/EU article 4, section 3. The filters can be delivered with approval according to category I, II, III or IV.