Product specifications

How much should be filtered:

Normally 5-15% of the flow through the main line should be filtered. In transmissi-on systems which are characterised by a limited amount of circulating liquid and a relatively high liquid flow rate filtration of 3-5% of the main flow will be sufficient. Transmission systems are mostly isolated circuits where contamination is relatively limited.

In distribution networks filtration of around 5-10% will be sufficient to protect the system if it is of more recent date and the filter is installed when the system is star-ted up. If partial flow filtration is installed in an older system where partial flow filtration has not previously been used 10-15% should be filtered to achieve a satis-factory result.

Where should the partial flow filter be installed:

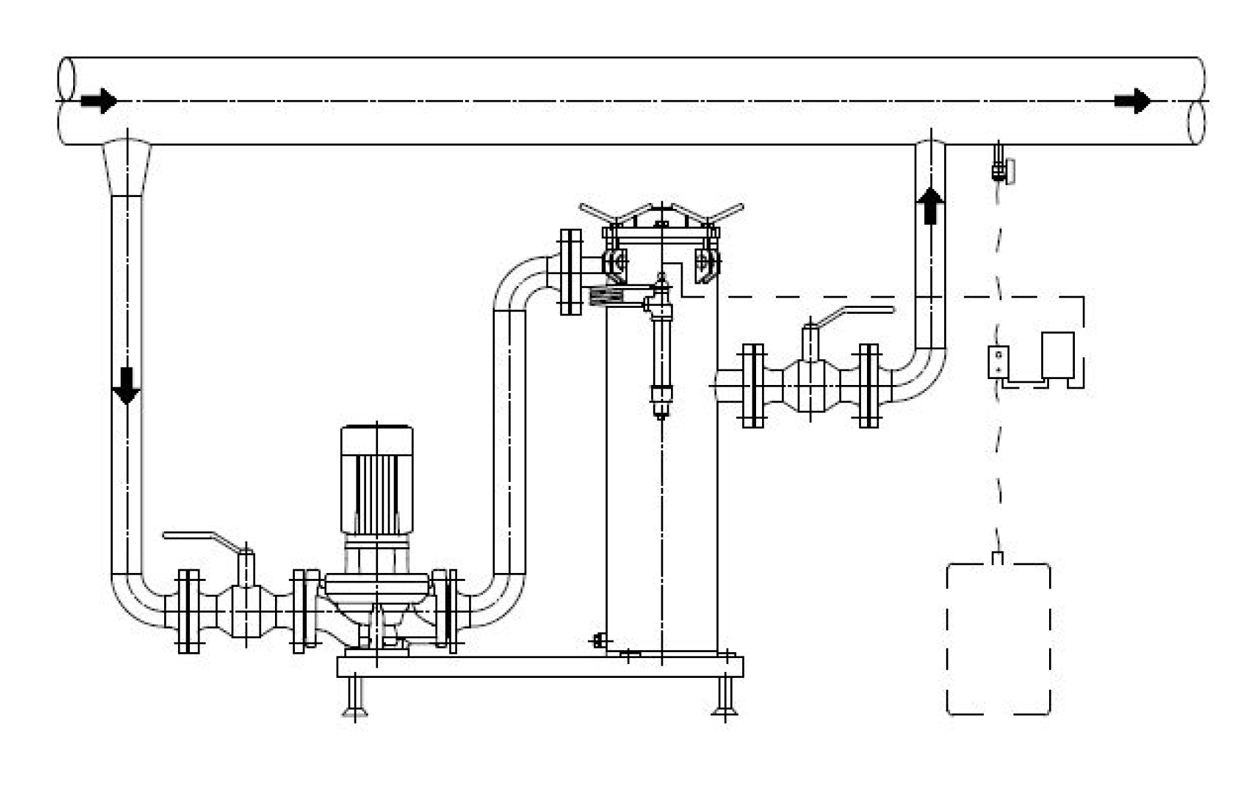

The partial flow filter should preferably be installed in the return pipe. This is where the temperature is lowest which increases the efficiency of the magnets. Magnets loose approximately 0.2% of their efficiency with each temperature increase of one degree Celsius.

The filter unit should be placed in the lower part of the system as particles precipi-tate and accumulate here. Dirt has a tendency to move in the system during start-up and when the flow is changed as a result of regulation or pressure surges. It should therefore be expected that the filter will fill with dirt faster on these occassions.

When connecting the partial flow unit to the main line it is vital that the connection to the inlet side of the unit is fitted at the bottom of the main line. This is because the dirt particles move along the bottom of the pipe. The connection should also be installed where the flow of liquid in the main line can be expected to be laminar. This means that the outlet from the main line to the unit should be located at least 8 to 10 times the pipe diameter of the main line from either a bend, valve or other

Design and production:

HiFlux Units are manufactured in a number of different versions of which the standardised units are shown on the following pages. All units accommodate current standards and norms for pressure vessels, conform to the EMC Directive and are CE-labelled. Approval in accordance with the Danish Working Environment Service, TüV, UDT etc. is possible. Filters of pressure class PN16 are manufactured in container steel with full traceability and continuos process control has been carried out. EN 10204 3.1.B material certificates, NDT report from welding test and check books are supplied in accordance with the official requirements of the place of use or as agreed.

Special versions can be made in co-operation with our design department.