HiFlux Auto-line® filters are designed as compact self-cleaning automatic filters with a wide range of applications for various types of liquids. The sturdy construction of the filter makes it well suited for industrial and hygienic applications in which operational reliability and dependability are essential.

The industrial Auto-line® filter is used in many sectors such as paint, cooling water, waste water, technical water, heat exchanger, chemicals, resins and energy sector. The hygienic Auto-line® filter is used in sectors such as: various cheese products, chocolate, coffee, honey, egg, beverage, oil and fats, sugar and CIP liquids.

The Auto-line® filter is used when an automatic continuous cleaning process is required. The impurities are being concentrated in the filter, until it is drained away, while the filter is still in operation the liquid loss due to cleaning is minimal.

The Auto-line® filters are also available as R-E versions, where the scraping process is driven by an electric gear-motor or as the P version, where the scraping process is driven by a pneumatic actuator. The E filter versions has an extended pneumatic cylinder, so that cross contamination between the liquid to be filtered and the pneumatic system is avoided.

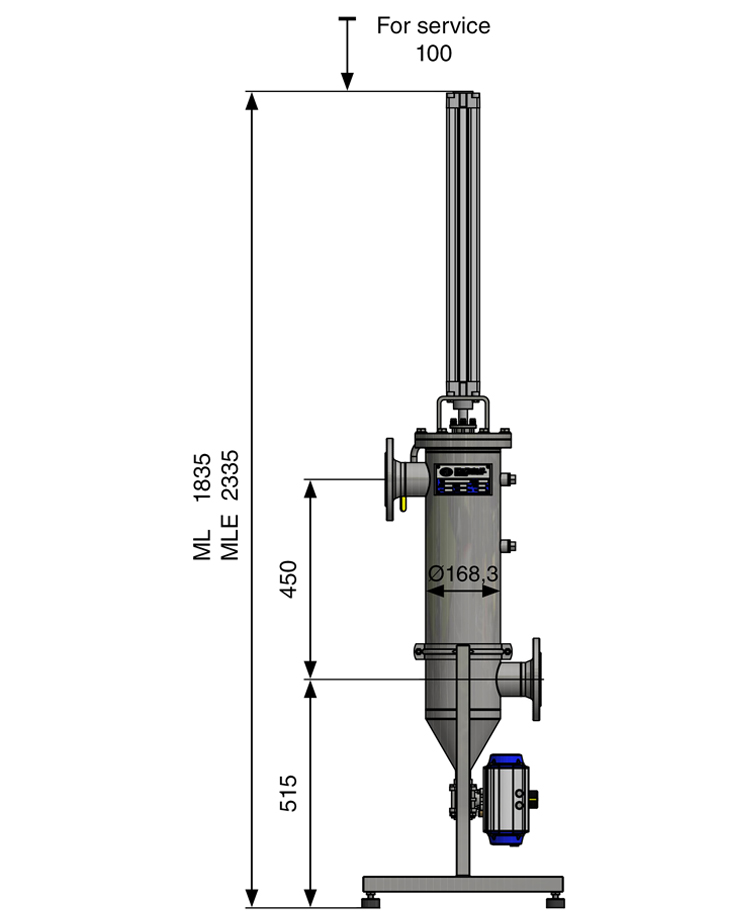

In the design of the filter it was very important to make the construction robust and reliable. By limiting the number of moving components, wear and maintenance requirements are minimized. The simple construction makes the filter very easy to service, since there is no need for external service assistance or special tools. Furthermore, the compact design of the filter is making it suitable for locations, where the height is a limitation.

Special versions can be supplied according to customer requirements.

Typically different connections, temperature and pressure levels.

HiFlux Auto-line® filters are designed as compact self-cleaning automatic filters with a wide range of applications for various types of liquids. The sturdy construction of the filter makes it well suited for industrial and hygienic applications in which operational reliability and dependability are essential.

The industrial Auto-line® filter is used in many sectors such as paint, cooling water, waste water, technical water, heat exchanger, chemicals, resins and energy sector. The hygienic Auto-line® filter is used in sectors such as: various cheese products, chocolate, coffee, honey, egg, beverage, oil and fats, sugar and CIP liquids.

The Auto-line® filter is used when an automatic continuous cleaning process is required. The impurities are being concentrated in the filter, until it is drained away, while the filter is still in operation the liquid loss due to cleaning is minimal.

The Auto-line® filters are also available as R-E versions, where the scraping process is driven by an electric gear-motor or as the P version, where the scraping process is driven by a pneumatic actuator. The E filter versions has an extended pneumatic cylinder, so that cross contamination between the liquid to be filtered and the pneumatic system is avoided.

In the design of the filter it was very important to make the construction robust and reliable. By limiting the number of moving components, wear and maintenance requirements are minimized. The simple construction makes the filter very easy to service, since there is no need for external service assistance or special tools. Furthermore, the compact design of the filter is making it suitable for locations, where the height is a limitation.

Special versions can be supplied according to customer requirements.

Typically different connections, temperature and pressure levels.