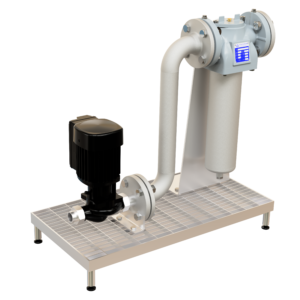

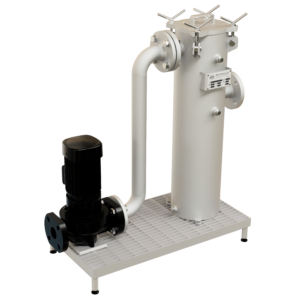

HiFlux Micro-line 1050 filters are designed as compact inline universal filters with many applications.

The filter is supplied as a bag or strainer filters and both versions can be fitted with a magnetic system for efficient retention of magnetic particles.

The filter housing is made from EN-GJS-500-7 cast iron and stainless acid-proof EN 1.4404 steel and designed for a 16 bar working pressure at temperatures of up to 110 °C -(water) or by assignment.

The lid is designed in such a way that it can be opened and closed quickly -without using tools, and the built-in locking function ensures that the filter cannot be opened by accident when it is under pressure.

In the bag filter version the filter is used where there is a need for reliable fine filtration from 1 micron with a large dirt capacity. Filter bags are available in several material types and filtration ranges (see also data sheet for filter bags).

In the strainer filter version the filter is used where there is a need for a large flow and dirt capacity and a small differential pressure.

In the standard version the direction of flow is from the inside and out through the filter insert. The dirt is retained in the filter insert, which can be lifted out and cleaned. It is possible to use the strainer filter with reverse flow. This means that the dirt is retained on the outside of the strainer and it is possible to remove the sludge from the filter by fitting a valve into the drain.

The filter can be fitted with a unique magnetic system which makes it possible to retain magnetic particles as small as less than 1 micron. The magnetic insert is designed as an integrate part of the bag/strainer insert for simple and fast handling -again without any use of tools -in connection with cleaning.

The magnetic insert is of the HiFlux type which is fitted with Neodymium magnets. In comparison to conventional ceramic magnets provides a magnetic field which is seven times stronger, resulting in significant increases in both efficiency and capacity.

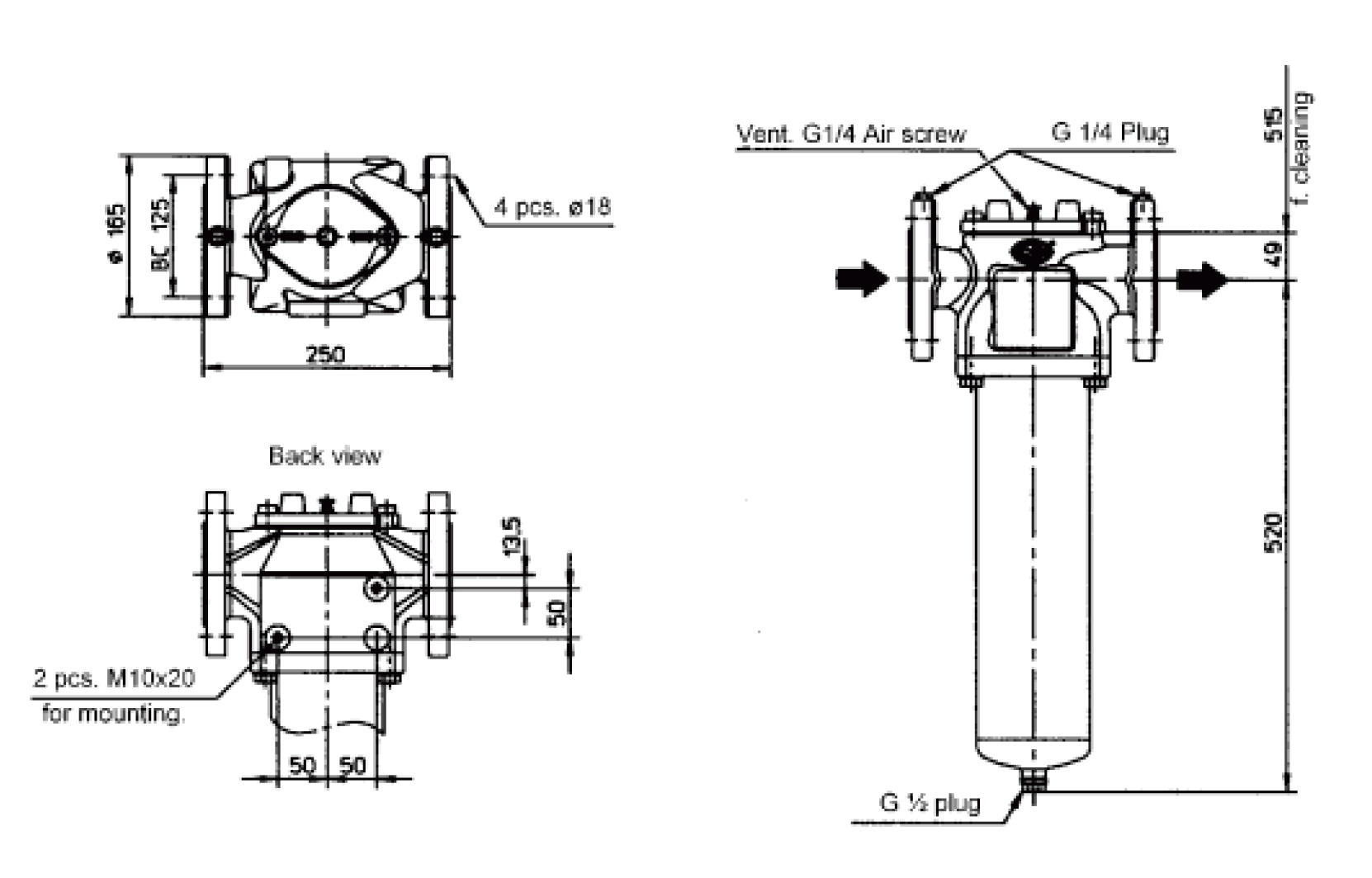

A standard differential pressure indicator with an electrical outlet has been de-veloped especially for this filter. The indicator shows an area from 0 -1,0 bar. In general cleaning of the filter is recommended at 0,8 bar. With the electrical outlet it is also possible to transfer a signal for remote reading (see also data sheet for pressure indicators).

Fittings for suspending the filter can also be supplied as an extra option and should be fitted directly on to the filter housing.If a smaller connection size is required, a set of two counterflanges drilled with a G1B, or a G3/4 B threaded joint including bolts and washers can be supplied.

For other options see also HiFlux Micro-line 1050 SS, HiFlux TS and HiFlux TP filters.

HiFlux Micro-line 1050 filters are designed as compact inline universal filters with many applications.

The filter is supplied as a bag or strainer filters and both versions can be fitted with a magnetic system for efficient retention of magnetic particles.

The filter housing is made from EN-GJS-500-7 cast iron and stainless acid-proof EN 1.4404 steel and designed for a 16 bar working pressure at temperatures of up to 110 °C -(water) or by assignment.

The lid is designed in such a way that it can be opened and closed quickly -without using tools, and the built-in locking function ensures that the filter cannot be opened by accident when it is under pressure.

In the bag filter version the filter is used where there is a need for reliable fine filtration from 1 micron with a large dirt capacity. Filter bags are available in several material types and filtration ranges (see also data sheet for filter bags).

In the strainer filter version the filter is used where there is a need for a large flow and dirt capacity and a small differential pressure.

In the standard version the direction of flow is from the inside and out through the filter insert. The dirt is retained in the filter insert, which can be lifted out and cleaned. It is possible to use the strainer filter with reverse flow. This means that the dirt is retained on the outside of the strainer and it is possible to remove the sludge from the filter by fitting a valve into the drain.

The filter can be fitted with a unique magnetic system which makes it possible to retain magnetic particles as small as less than 1 micron. The magnetic insert is designed as an integrate part of the bag/strainer insert for simple and fast handling -again without any use of tools -in connection with cleaning.

The magnetic insert is of the HiFlux type which is fitted with Neodymium magnets. In comparison to conventional ceramic magnets provides a magnetic field which is seven times stronger, resulting in significant increases in both efficiency and capacity.

A standard differential pressure indicator with an electrical outlet has been de-veloped especially for this filter. The indicator shows an area from 0 -1,0 bar. In general cleaning of the filter is recommended at 0,8 bar. With the electrical outlet it is also possible to transfer a signal for remote reading (see also data sheet for pressure indicators).

Fittings for suspending the filter can also be supplied as an extra option and should be fitted directly on to the filter housing.If a smaller connection size is required, a set of two counterflanges drilled with a G1B, or a G3/4 B threaded joint including bolts and washers can be supplied.

For other options see also HiFlux Micro-line 1050 SS, HiFlux TS and HiFlux TP filters.